7 PARAMETERS

7.2 Detailed list of parameters

201

7

■

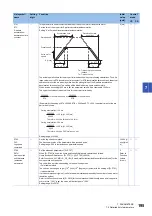

Setting example of a conveyor

Machine specifications

Pulley diameter: r = 160 [mm]

Reduction ratio: 1/n = Z

1

/Z

2

= 1/3

Z

1

: Number of gear teeth on servo motor side

Z

2

: Number of gear teeth on load gear

Servo motor encoder resolution: P

t

= 4194304 [pulse/rev]

*1 Because the command unit is "mm",

= 1000 is set. When the unit is "inch",

is 10000. When the unit is "pulse",

is 1.

Reduce CMX and CDV to within the setting range or lower, and round off each value to the closest whole number.

Therefore, set CMX = 524288 and CDV = 20944.

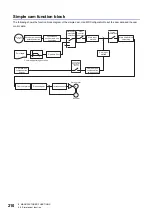

Electronic gear setting in the indexer method

Using [Pr. PA06] and [Pr. PA07], adjust the rotation amount "m" of the servo motor shaft which is required to rotate the load

side for "n" times. The following shows a setting example of the electronic gear.

■

Number of pulley teeth on machine side: 50, number of pulley teeth on servo motor side: 20

Set [Pr. PA06] = 50 and [Pr. PA07] = 20.

■

Number of pulley teeth on machine side: 50, number of pulley teeth on servo motor side: 20,

with geared servo motor of 1/9

Set [Pr. PA06] = 450 and [Pr. PA07] = 20.

4194304 [pulse/rev]

Z

1

Z

2

1/n = Z

1

/Z

2

= 1/3

1/n

r = 160 [mm]

Servo motor encoder resolution

CMX

CDV

P

t

=

ΔS

P

t

=

1/n • r • π • α *1

4194304

=

1/3 • 160 • π • 1000

4194304

=

167551.61

524288

¬

20944

Number of pulley teeth on

machine side: 50

Servo motor

Number of pulley teeth on

servo motor side: 20

×

=

450

20

9

1

50

20

Number of pulley teeth on

machine side: 50

Servo motor

Number of pulley teeth on

servo motor side: 20

Reduction ratio of geared

servo motor: 1/9