9 MANUFACTURER FUNCTIONS

9.5 Simple cam function

235

9

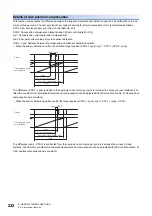

Restart operation of cam control

When the cam control is stopped during operation, a gap may be generated in the synchronous position relationship between

the main shaft and the driven shaft. To solve the gap, return the main shaft and the driven shaft to the synchronization starting

point and then start the synchronous operation.

The above shows an example for when the synchronization starting point is the point where both command position and feed

current value are "0".

ON

OFF

ON

OFF

ON

OFF

ON

OFF

*1

1

2

*1

*1

*1

Controlword bit 4

(New set-point)

Control DI 2 bit 5

Status DO 2 bit 5

0 r/min

0 r/min

Controlword bit 4

(New set-point)

Main shaft/driven shaft

Servo-on

Point table in which the command

position 0 is set as the target position

5 ms or longer

Point table No.

3 ms or shorter

Main shaft

Positioning to the synchronization

start position (Command position 0)

Point table No. 1

Forward

rotation

Command speed

Reverse

rotation

Command position

Driven shaft

3 ms or shorter

Positioning to the synchronization

start position (Feed current value 0

(= Command position 0))

Point table No. 1

Forward

rotation

Command speed

Reverse

rotation

If the cam control stops during

operation, the synchronous position

relationship with the main shaft is

broken.

Command position

Cam axis one cycle

current value

Cam axis feed current value

5 ms or shorter