220

9 MANUFACTURER FUNCTIONS

9.5 Simple cam function

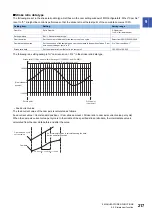

• Feed current value

The feed current value of the cam axis is calculated as follows:

Feed current value = Cam standard po Output value to cam axis current value per cycle

When the cam axis current value per cycle is in the middle of the specified stroke ratio data, the intermediate value is

calculated from the cam data before and after the value.

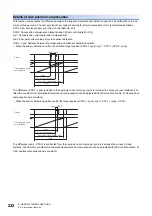

• Cam standard position

The cam standard position is calculated as follows:

The preceding cam standard po Output value corresponding to "Input value = Cam axis one cycle length" - Output

value corresponding to "Input value = 0"

For to-and-fro control, use the output value corresponding to "Input value = Cam axis length per cycle" that is equal to output

value corresponding to "Input value = 0".

• Cam data start position

This is not used in the coordinate data type.

• Timing of applying cam control data

New values are applied to "Cam No." when bit 5 of Control DI2 (2D02h) turns on.

"Cam standard position" is updated when the cam axis current value per cycle passes through "0".

Cam axis

one cycle current value

Cam data

One resolution or between

two coordinates

An intermediate value is calculated using the

data before and after the value.

t

t

Cam axis one cycle

current value

Cam standard

position

(Third cycle)

Cam standard

position

(Second cycle)

Cam standard

position

(First cycle)

Feed current value

Output value corresponding to

"Input value = Cam axis one cycle length" - Output value corresponding to "Input value = 0"

t

t

Cam axis one cycle

current value

Feed current value

Cam standard position

(Does not change because the output value is 0.)