200

7 PARAMETERS

7.2 Detailed list of parameters

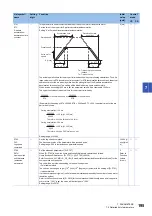

How to set the electronic gear

Electronic gear settings in the point table method

Adjust [Pr. PA06] and [Pr. PA07] to match the servo amplifier setting with the travel distance of the machine.

Pt: Servo motor encoder resolution: 4194304 [pulse/rev]

S: Travel distance per servo motor revolution [mm/rev]/[inch/rev]/[pulse/rev]

CMX/CDV = Pt/

S

The following setting example shows how to calculate the electronic gear.

• To calculate the electronic gear, the following symbols are required.

Pb: Ball screw lead [mm]

1/n: Reduction ratio

Pt: Servo motor encoder resolution [pulse/rev]

S: Travel distance per servo motor revolution [mm/rev]

■

Setting example of a ball screw

Machine specifications

Ball screw lead Pb = 10 [mm]

Reduction ratio: 1/n = Z

1

/Z

2

= 1/2

Z

1

: Number of gear teeth on servo motor side

Z

2

: Number of gear teeth on load gear

Servo motor encoder resolution: P

t

= 4194304 [pulse/rev]

*1 Because the command unit is "mm",

= 1000 is set. When the unit is "inch",

is 10000. When the unit is "pulse",

is 1.

Therefore, set CMX = 524288 and CDV = 625.

CDV

CMX

+

-

M

Electronic gear

([Pr. PA06]/[Pr. PA07])

Servo motor

Travel distance

Deviation counter

Encoder

4194304 [pulse/rev]

Pb = 10 [mm]

Z

1

1/n = Z

1

/Z

2

= 1/2

Z

2

1/n

Servo motor encoder resolution

CMX

CDV

P

t

=

ΔS

P

t

=

1/n • Pb • α

*1

4194304

=

1/2 • 10 • 1000

4194304

=

5000

524288

=

625