Brakes & Wheels

277

Automatic Brake Adjuster Checking Procedures

If the brake adjuster is not maintaining the proper applied stroke, before removing the brake adjuster,

check the condition of the foundation brake. If after inspecting the foundation brake no apparent prob-

lems are found, inspect the automatic brake adjuster to determine if it is operating properly. The inspec-

tion can be performed on or off the vehicle using the following procedures.

Block wheels to prevent vehicle from rolling.

Ensure system tank pressure is at 90-100 psi.

Check that push rod is fully retracted; apply air to release spring

brake.

If air is not available, spring brake must be manually caged back.

Do not use air tools on brake adjuster!

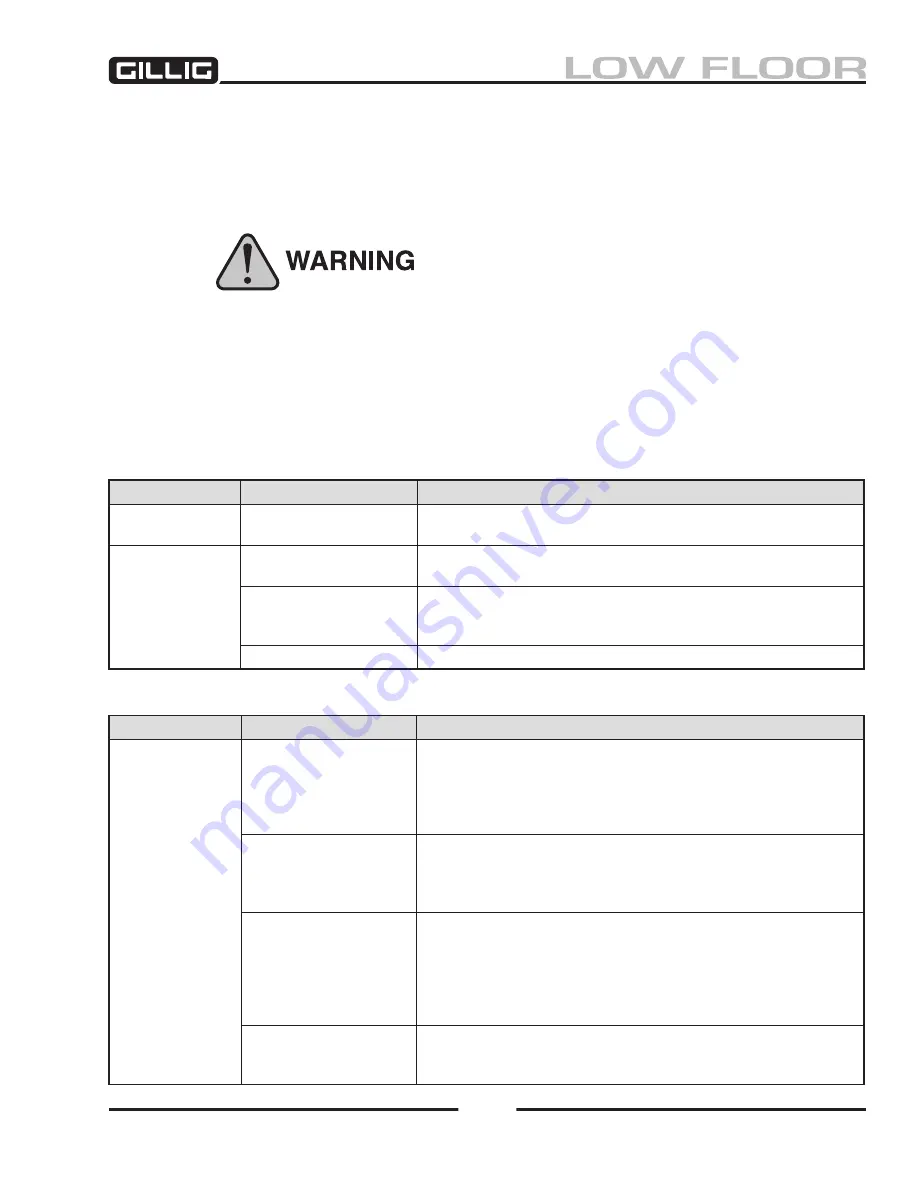

On Vehicle Inspection

Component

Cause

Action

Tight or dragging

brakes

Control arm mispositioned

Realign control arm and anchor bracket. Check “Installing Haldex

Automatic Slack Adjusters.”

Excessive chamber

push rod travel

Improper anchor bracket

connection to control arm

If anchor bracket to control arm connection is worn, loose, bent or

broken, it must be re-secured or replaced.

Low clutch torque

Rotate the 7/16" adjustment hex one full turn counterclockwise.

Replace brake adjuster if the torque is less than 13 ft-lb or no ratcheting

sound occurs.

Unknown

Perform automatic brake adjuster operational check (see below).

Off Vehicle Inspection

Component

Cause

Action

Adjuster not func-

tioning properly

Low clutch torque

Place adjuster arm in vise. Rotate the 7/16" adjustment hex counter

-

clockwise one full turn to check de-adjustment torque. After control arm

stops rotating, a minimum of 13 ft-lb will be required and a ratchet

-

ing sound will occur. Replace brake adjuster if the torque is less than

13 ft-lb or no de-adjustment ratcheting sound is present.

Control arm slippage

Place adjuster arm in vise. Rotate the control arm counterclockwise

until the control arm rotates to an INTERNAL STOP. If the installation

indicator goes past the indicator notch or does not stop rotating (arm

slips freely), replace the brake adjuster.

Unknown

If torque is above 13 ft-lb, scribe a line on the adjustment hex. Manually

pull the brake adjuster control arm clockwise then push back counter-

clockwise until the installation indicator stops in the indicator notch.

The hex will move in a clockwise direction when the control arm of the

brake adjuster is pushed back counterclockwise. Replace adjuster if hex

does not move.

Worn/missing control arm

wear bushing, and anchor

stud pin, if applicable

Remove and replace pin and bushings. If adjuster has passed the above

checks, re-install adjuster on vehicle, with new hardware.

•

•

•

•

•

Содержание LOW FLOOR

Страница 18: ...Specifications 18...

Страница 58: ...Preventive Maintenance 58...

Страница 110: ...Engine 110...

Страница 138: ...Transmission Driveline Rear Axle 138...

Страница 182: ...Suspension 182...

Страница 260: ...Air System 260...

Страница 420: ...Electrical System 420 Deutsch DT Series Connectors...

Страница 421: ...Electrical System 421...

Страница 422: ...Electrical System 422 Deutsch HD 10 Series Connectors...

Страница 423: ...Electrical System 423...

Страница 424: ...Electrical System 424 Deutsch HD 30 Series Connectors...

Страница 425: ...Electrical System 425...

Страница 442: ...Heating Air Conditioning 442...

Страница 486: ...Body and Interior 486 Driver s Seat Troubleshooting Use the following chart to troubleshoot the USSC seat...

Страница 492: ...Body and Interior 492 Figure 11 33 USSC Seat Assembly...

Страница 493: ...Body and Interior 493 Figure 11 34 USSC Seat Suspension Assembly...

Страница 495: ...Body and Interior 495 Figure 11 37 Seat Air Connections...

Страница 506: ...GILLIG CORPORATION 25800 Clawiter Road Hayward CA 94545 Phone 510 785 1500 Fax 510 785 6819 Printed November 2006...