SECTION

4

- BOO

M

& PLATFOR

M

4-16

3121160

Inspection

NOTE:

When inspecting pins and bearings Refer to Section 2, Pins

and Composite Bearing Repair Guidelines.

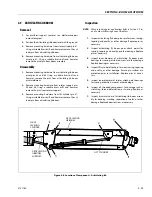

1.

Inspect main boom pivot pin for wear, scoring, tapering

and ovality, or other damage. Replace pins as necessary.

2.

Inspect telescope cylinder attach point for scoring,

tapering and ovality. Replace pins as necessary.

3.

Inspect upper lift cylinder attach pin for wear, scoring,

tapering and ovality, or other damage. Ensure pin sur-

faces are protected prior to installation. Replace pins as

necessary.

4.

Inspect inner diameter of boom pivot bearing for scor-

ing, distortion, wear, or other damage. Replace bearing

as necessary. (See Section 5, Cylinder Repair for bearing

replacement).

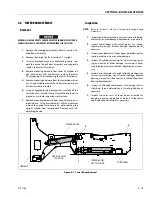

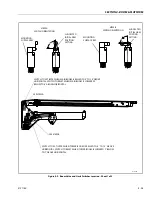

5.

Inspect all wear pads for excessive wear, or other dam-

age. Replace pads when worn as specified in Figure 4-

12., Location and Thickness of Wear Pads.

6.

Inspect all threaded components for damage such as

stretching, thread deformation, or twisting. Replace as

necessary.

7.

Inspect structural units of boom assembly for bending,

cracking, separation of welds, or other damage. Replace

boom sections as necessary.

Assembly

NOTE:

When installing fly section wear pads, install same number

and thickness of shims as were removed during disassem-

bly.

1.

Measure inside dimensions of the base section to deter-

mine the number of shims required for proper fit.

2.

Install side, top and bottom wear pads to the aft end of

fly section; shim evenly to the measurements of the

inside of base boom section.

WHEN ASSEMBLING BOOM SECTIONS, ENSURE THAT THE BOOM SLIDING TRA-

JECTORIES HAVE BEEN CLEARED OF CHAINS, TOOLS, AND OTHER OBSTRUC-

TIONS.

3.

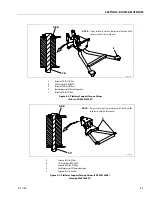

Secure the sling and lifting device at the telescope cylin-

der’s approximate center of gravity, and lift the cylinder

to the aft end of the fly boom section.

4.

Slide telescope cylinder into the aft end of fly boom sec-

tion. Align attachment holes in fly boom section with

hole in rod end of telescope cylinder.

5.

Install telescope cylinder pin and secure with mounting

hardware.

6.

Secure the sling and lifting device at the fly boom

assembly approximate center of gravity.

7.

Slide fly boom assembly into the base boom section.

Shim boom, if necessary, for a total of 1/32 in. (0.8 mm)

clearance.

8.

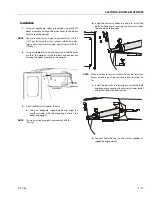

Install wear pads into the forward position of the base

boom section. Shim boom, if necessary, for a total of

1/32 in. (0.8 mm) clearance.

9.

Align the cylinder with the slots at aft end of base boom

section, then secure cylinder with mounting hardware.

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......