SECTION 5 - BASIC HYDRAULIC INFOR

M

ATION AND SCHE

M

ATICS

5-40

3121160

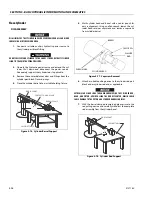

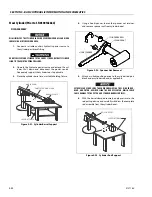

8.

Using suitable protection, clamp the cylinder rod in a

vise or similar holding fixture as close to the piston as

possible.

9.

Remove capscrews from drilled holes.

10.

Insert the capscrews in the threaded holes in the outer

piece of the tapered bushing. Progressively tighten the

capscrews until the bushing is loosen on the piston.

11.

Remove the bushing from the piston.

12.

Screw the piston counterclockwise by hand and remove

the piston from cylinder rod.

13.

Remove and discard the piston hydrolock seals, guide-

lock rings, o-ring, and backup rings.

14.

Remove piston spacer from rod.

15.

Remove the rod from the holding fixture. Remove the

cylinder head gland. Remove and discard the o-rings,

backup rings, wear ring, rod seal, and wiper seal.

CLEANING AND INSPECTION

1.

Clean all parts thoroughly in an approved cleaning sol-

vent.

2.

Inspect the cylinder rod for scoring, tapering, ovality, or

other damage. If necessary, dress rod with Scotch Brite

or equivalent. Replace rod if necessary.

3.

Inspect threaded portion of rod for excessive damage.

Dress threads as necessary.

4.

Inspect inner surface of cylinder barrel tube for scoring

or other damage. Check inside diameter for tapering or

ovality. Replace if necessary.

5.

Inspect threaded portion of barrel for damage. Dress

threads as necessary.

6.

Inspect piston surface for damage and scoring and for

distortion. Dress piston surface or replace piston as nec-

essary.

7.

Inspect threaded portion of piston for damage. Dress

threads as necessary.

8.

Inspect seal and o-ring grooves in piston for burrs and

sharp edges. Dress applicable surfaces as necessary.

9.

Inspect cylinder head inside diameter for scoring or

other damage, and for ovality and tapering. Replace as

necessary.

10.

Inspect threaded portion of head for damage. Dress

threads as necessary.

11.

Inspect seal and o-ring grooves in head for burrs and

sharp edges. Dress applicable surfaces as necessary.

12.

Inspect cylinder head outside diameter for scoring or

other damage and ovality and tapering. Replace as nec-

essary.

13.

If applicable, inspect rod and barrel bearings for signs of

correct excessive wear or damage. Replace as necessary.

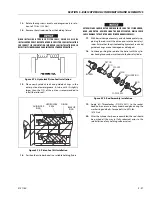

a.

Thoroughly clean hole, (steel bushing) of burrs, dirt

etc. to facilitate bearing installation.

b.

Inspect steel bushing for wear or other damage. If

steel bushing is worn or damaged, rod/barrel must

be replaced.

c.

Lubricate inner side of steel bushing with prior to

bearing installation.

d.

Using an arbor of the correct size, carefully press the

bearing into steel bushing.

NOTE:

Install pin into the composite bearing dry. Lubrication is

not required with nickel plated pins and bearings.

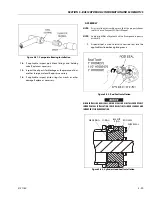

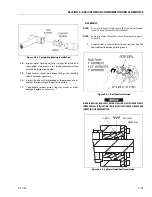

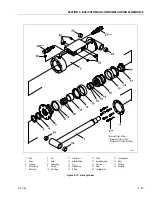

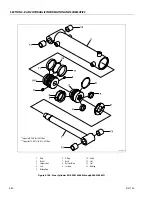

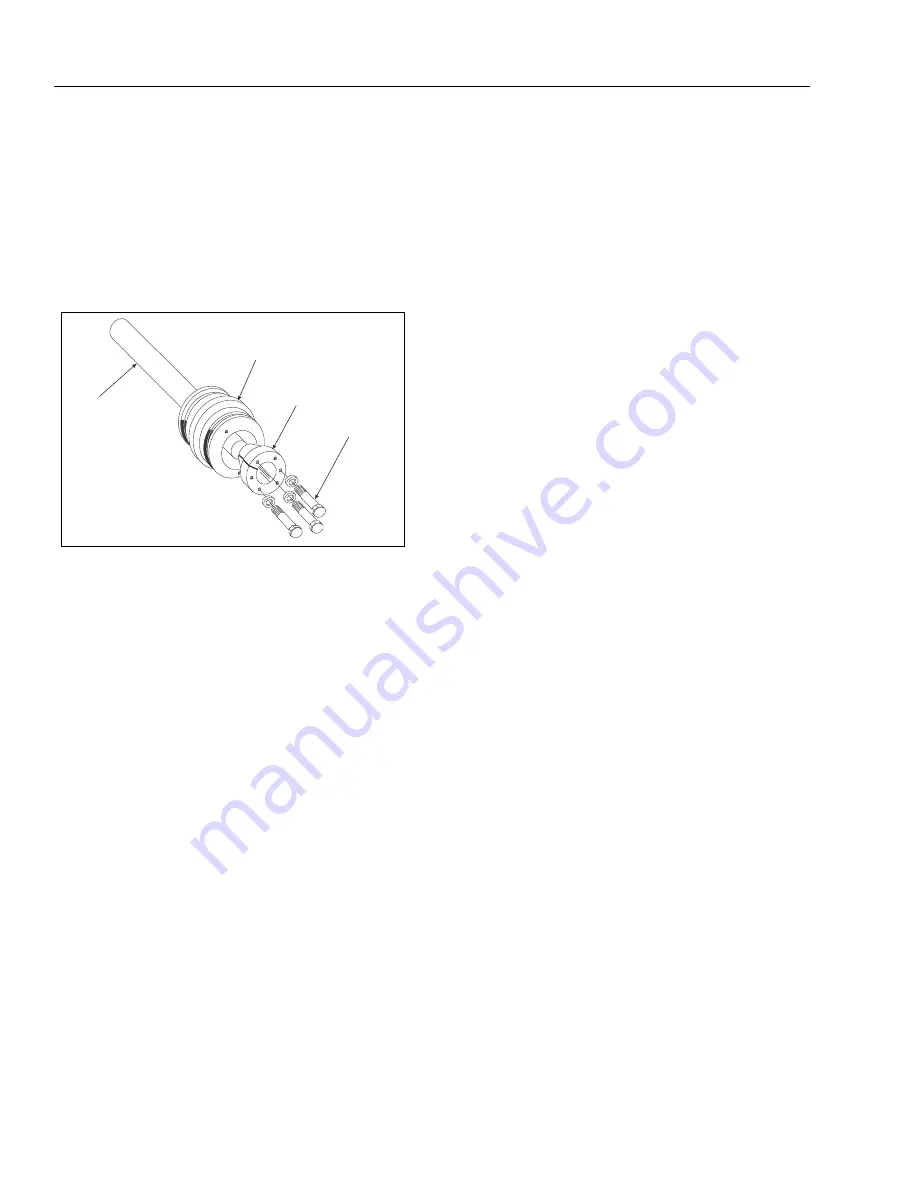

TAPERED

BUSHING

ROD

CAPSCREW

PISTON

Figure 5-80. Tapered Bushing Removal

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......