SECTION

4

- BOO

M

& PLATFOR

M

3121160

4-45

Testing the Actuator

If the equipment is available, the actuator should be tested on a

hydraulic test bench. The breakaway pressure — the pressure at

which the shaft begins to rotate — should be approximately 400

psi (28 bar). Cycle the actuator at least 25 times at 3000 psi (210

bar) pressure. After the 25 rotations, increase the pressure to

4500 psi (315 bar) to check for leaks and cracks. Perform the test

again at the end of the rotation in the opposite direction.

TESTING THE ACTUATOR FOR INTERNAL LEAKAGE

If the actuator is equipped with a counterbalance valve, plug the

valve ports. Connect the hydraulic lines to the housing ports.

Bleed all air from the actuator (see Installation and Bleeding)

Rotate the shaft to the end of rotation at 3000 psi (210 bar) and

maintain pressure. Remove the hydraulic line from the non-pres-

surized side.

Continuous oil flow from the open housing port indicates inter-

nal leakage across the piston. Replace the line and rotate the

shaft to the end of rotation in the opposite direction. Repeat the

test procedure outlined above for the other port. If there is an

internal leak, disassemble, inspect and repair.

Installation and Bleeding

After installation of the actuator on the equipment, it is impor-

tant that all safety devices such as tie rods or safety cables are

properly reattached.

To purge air from the hydraulic lines, connect them together to

create a closed loop and pump hydraulic fluid through them.

Review the hydraulic schematic to determine which hydraulic

lines to connect. The linear feet and inside diameter of the

hydraulic supply lines together with pump capacity will deter-

mine the amount of pumping time required to fully purge the

hydraulic system.

Bleeding may be necessary if excessive backlash is exhibited

after the actuator is connected to the hydraulic system. The fol-

lowing steps are recommended when a minimum of two gallons

(8 liters) is purged.

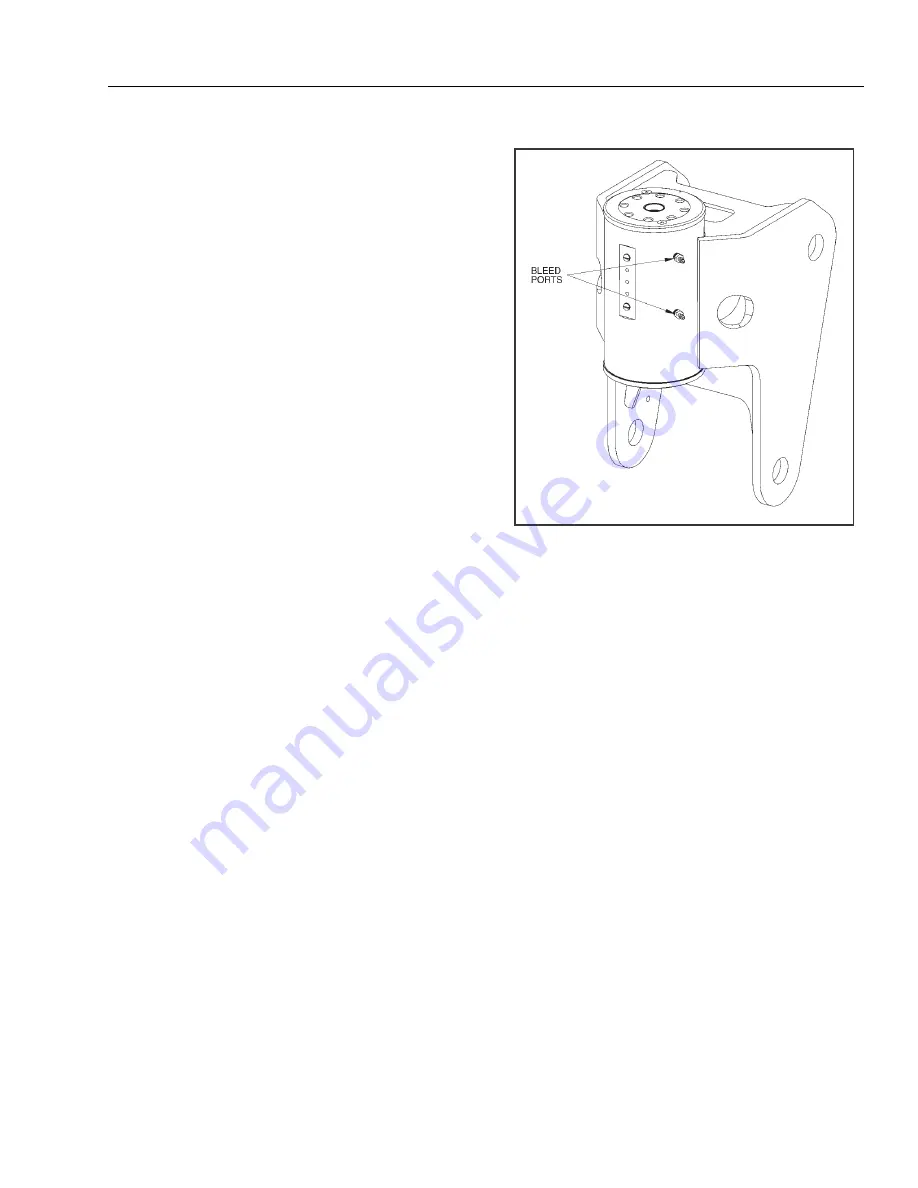

1.

Connect a 3/16 in. inside diameter x 5/16 in. outside

diameter x 5 foot clear, vinyl drain tube to each of the

two bleed nipples. Secure them with hose clamps. Place

the vinyl tubes in a clean 5-gallon container to collect

the purged oil. The oil can be returned to the reservoir

after this procedure is completed.

2.

With an operator in the platform, open both bleed nip-

ples 1/4 turn. Hydraulically rotate the platform to the

end of rotation (either clockwise or counterclockwise),

and maintain hydraulic pressure. Oil with small air bub-

bles will be seen flowing through the tubes. Allow a 1/2

gallon of fluid to be purged from the actuator.

3.

Keep the fittings open and rotate the platform in the

opposite direction to the end position. Maintain hydrau-

lic pressure until an additional 1/4 gallon of fluid is

pumped into the container.

4.

Repeat steps 2 & 3. After the last 1/2 gallon is purged,

close both bleed nipples before rotating away from the

end position.

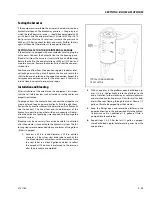

TYPICAL CONFIGURATION

OF ACTUATOR

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

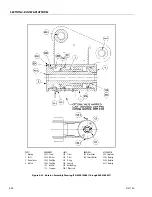

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......