SECTION 3 - CHASSIS & TURNTABLE

3-116

3121160

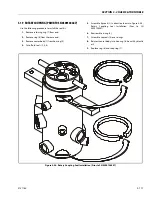

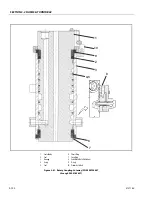

One Piece Stator Construction

A disassembled rotor (8A) stator (8B) and vanes (8C) that can-

not be readily assembled by hand can be assembled by the

following procedures.

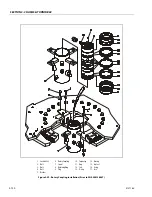

1.

Place stator (8B) onto wear plate (9) with seal ring (4)

side down, after following Torqmotor™ assembly proce-

dures 1 through 13. Be sure the seal ring is in place.

2.

If assembly alignment studs are not being utilized, align

stator bolt holes with wear plate and housing bolt holes

and turn two bolts (1) finger tight into bolt holes

approximately 180 degrees apart to retain stator and

wear plate stationary.

3.

Assemble the rotor (8A), counterbore down if applica-

ble, into stator (8B), and onto wear plate (9) with rotor

splines into mesh with drive link (10) splines.

NOTE:

If the manifold side of the rotor was etched during Torqmo-

tor disassembly, this side should be up. If the rotor is not

etched and does not have a counterbore, use the drive link

spline contact pattern apparent on the rotor splines to

determine the rotor side that must be against the wear

plate.

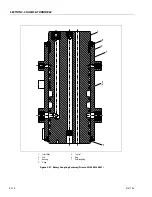

4.

Assemble six vanes (8C), or as many vanes that will read-

ily assemble into the stator vane pockets.

EXCESSIVE FORCE USED TO PUSH THE ROTOR VANES INTO PLACE COULD

SHEAR OFF THE COATING APPLIED TO THE STATOR VANE POCKETS.

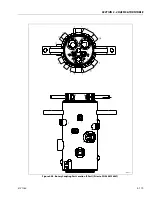

5.

Grasp the output end of coupling shaft (12) with locking

pliers or other appropriate turning device and rotate

coupling shaft, drive link and rotor to seat the rotor and

the assembled vanes (8C) into stator (8B), creating the

necessary clearance to assemble the seventh or full

complement of seven vanes. Assemble the seven vanes

using minimum force.

6.

Remove the two assembled bolts (1) if used to retain sta-

tor and wear plate.

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......