SECTION

4

- BOO

M

& PLATFOR

M

4-46

3121160

Troubleshooting

Table 4-1. Troubleshooting

Problem

Cause

Solution

1.

Shaft rotates slowly or not at all

a. Insufficient torque output

b. Low rate of fluid flow

c. Control or counterbalance valve has internal leak

d. Piston and/or shaft seal leak

e. Corrosion build-up on the thrust surfaces

f. Swollen seals and composite bearings caused by incom-

patible hydraulic fluid

a. Verify correct operating pressure. Do not exceed OEM’s

pressure specifications. Load may be above maximum

capacity of the actuator.

b. Inspect ports for obstructions and hydraulic lines for

restrictions and leaks.

c. Disconnect hydraulic lines and bypass valve. Leave valve

ports open and operate the actuator through housing ports

(do not exceed OEM’s operating pressure). The valve must

be replaced if a steady flow of fluid is seen coming from the

valve ports.

d. Remove the plug and the housing’s valve ports. Operate

the actuator through the housing ports. Conduct the inter-

nal leakage test as described in the Testing section on page

24 of this manual.

e. Re-build the actuator. Remove all rust then polish.

Replacement parts may be needed.

f. Re-build the actuator. Use fluid that is compatible with

seals and bearings.

2.

Operation is erratic or not responsive

a. Air in actuator

a. Purge air from actuator. See bleeding procedures.

3.

Shaft will not fully rotate

a. Twisted or chipped gear teeth

b. Port fittings are obstructing the piston

a. Check for gear binding. Actuator may not be able to be re-

built and may need to be replaced. Damage could be a result

of overload or shock.

b. Check thread length of port fittings. Fittings should dur-

ing stroke not reach inside the housing bore.

4.

Selected position cannot be maintained

a. Control or counterbalance valve has internal leak

b. Piston and/or shaft seal leak

c. Air in actuator

a. Disconnect hydraulic lines and bypass valve. Leave valve

ports open and operate the actuator through housing ports

(do not exceed OEM’s operating pressure). The valve must

be replaced if a steady flow of fluid is seen coming from the

valve ports.

b. Remove the plug and the housing’s valve ports. Operate

the actuator through the housing ports. Conduct the inter-

nal leakage test as described in the Testing section on page

24 of this manual.

c. Purge air from actuator. See bleeding procedures.

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

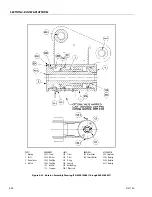

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......