SECTION 5 - BASIC HYDRAULIC INFOR

M

ATION AND SCHE

M

ATICS

3121160

5-87

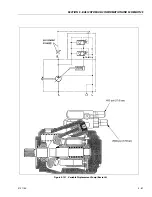

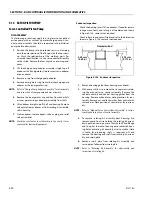

Shaft Seal Replacement

A lip type shaft seal is used in the pump and can be replaced

without major disassembly of the unit. Replacement of the

shaft seal requires removal of the pump from the machine.

REMOVAL

1.

Using the appropriate snap-ring pliers, remove the

retaining ring (K010) from the housing.

2.

Remove the shaft seal (K020) from the bore in the pump

housing and discard. Avoid damaging the pump hous-

ing or shaft. Puncture the face of the seal with a packing

hook, or use a slide-hammer type puller to remove the

seal.

INSTALLATION

1.

Inspect the pump housing and new seal for damage.

Inspect the sealing area on the shaft for rust, wear, or

contamination. Polish the sealing area on the shaft if

necessary.

2.

Lubricate the lip of the new shaft seal with clean hydrau-

lic fluid. Place a protective sleeve over the shaft end to

prevent damage to the seal during installation.

PREMATURE BEARING FAILURE CAN RESULT IF THE SHAFT SEAL CONTACTS

THE SHAFT BEARING. PRESS THE SEAL INTO THE HOUSING ONLY FAR ENOUGH

TO CLEAR THE RETAINING RING GROOVE.

3.

Keeping the seal perpendicular to the shaft, press the

new seal into the housing just far enough to clear the

retaining ring groove. Install seal with the cupped side

toward the shaft bearing. Do not damage the seal dur-

ing installation.

4.

Using the appropriate snap ring pliers, install the seal

retaining ring.

5.

Remove the installation sleeve.

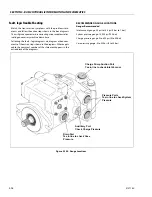

Control Assembly

K010

K020

Figure 5-133. Shaft Seal and Retaining Ring

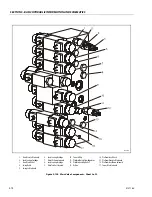

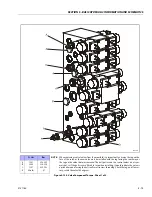

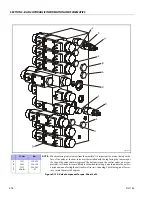

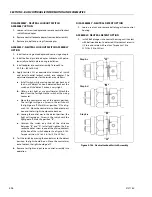

C117

C118

6mm

C116

C117

C114

C115

C113

C200

C138

6mm

C136

C135

C134

C133

C132

C103A

C112

C106A

C106

3/16 in

11-14 N•m

[8-10 lbf•ft]

C103

3/16 in

11-14 N•m

[8-10 lbf•ft]

C300 (4pl.)

5mm

15-18 N•m

[11-13 lbf•ft]

C102 (2pl.)

4mm

7-11 N•m

[6-8 lbf•ft]

C107A

C107

3/16 in

11-14 N•m

[8-10 lbf•ft]

Figure 5-134. Control Assembly

Summary of Contents for 740AJ

Page 2: ......

Page 55: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 3 This page left blank intentionally...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 64 3121160 Figure 3 44 Swing Hub Prior to SN 0300074383...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 151 Figure 3 77 EFI Component Location...

Page 206: ...SECTION 3 CHASSIS TURNTABLE 3 154 3121160 Figure 3 78 ECM EPM Identification ECM EPM...

Page 224: ...SECTION 3 CHASSIS TURNTABLE 3 172 3121160 Figure 3 83 Deutz EMR 2 Troubleshooting Flow Chart...

Page 228: ...SECTION 3 CHASSIS TURNTABLE 3 176 3121160 Figure 3 87 EMR 2 Engine Plug Pin Identification...

Page 229: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 177 Figure 3 88 EMR 2 Vehicle Plug Pin Identification...

Page 230: ...SECTION 3 CHASSIS TURNTABLE 3 178 3121160 Figure 3 89 EMR2 Fault Codes Sheet 1 of 5...

Page 231: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 179 Figure 3 90 EMR2 Fault Codes Sheet 2 of 5...

Page 232: ...SECTION 3 CHASSIS TURNTABLE 3 180 3121160 Figure 3 91 EMR2 Fault Codes Sheet 3 of 5...

Page 233: ...SECTION 3 CHASSIS TURNTABLE 3121160 3 181 Figure 3 92 EMR2 Fault Codes Sheet 4 of 5...

Page 234: ...SECTION 3 CHASSIS TURNTABLE 3 182 3121160 Figure 3 93 EMR2 Fault Codes Sheet 5 of 5...

Page 303: ...SECTION 4 BOOM PLATFORM 3121160 4 31 Figure 4 20 Rotator Assembly HELAC...

Page 460: ...SECTION 5 BASIC HYDRAULIC INFORMATION AND SCHEMATICS 5 116 3121160 NOTES...

Page 467: ...SECTION 6 JLG CONTROL SYSTEM 3121160 6 7 Figure 6 2 ADE Block Diagram...

Page 534: ...SECTION 6 JLG CONTROL SYSTEM 6 74 3121160 NOTES...

Page 580: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 46 3121160 NOTES...

Page 581: ......