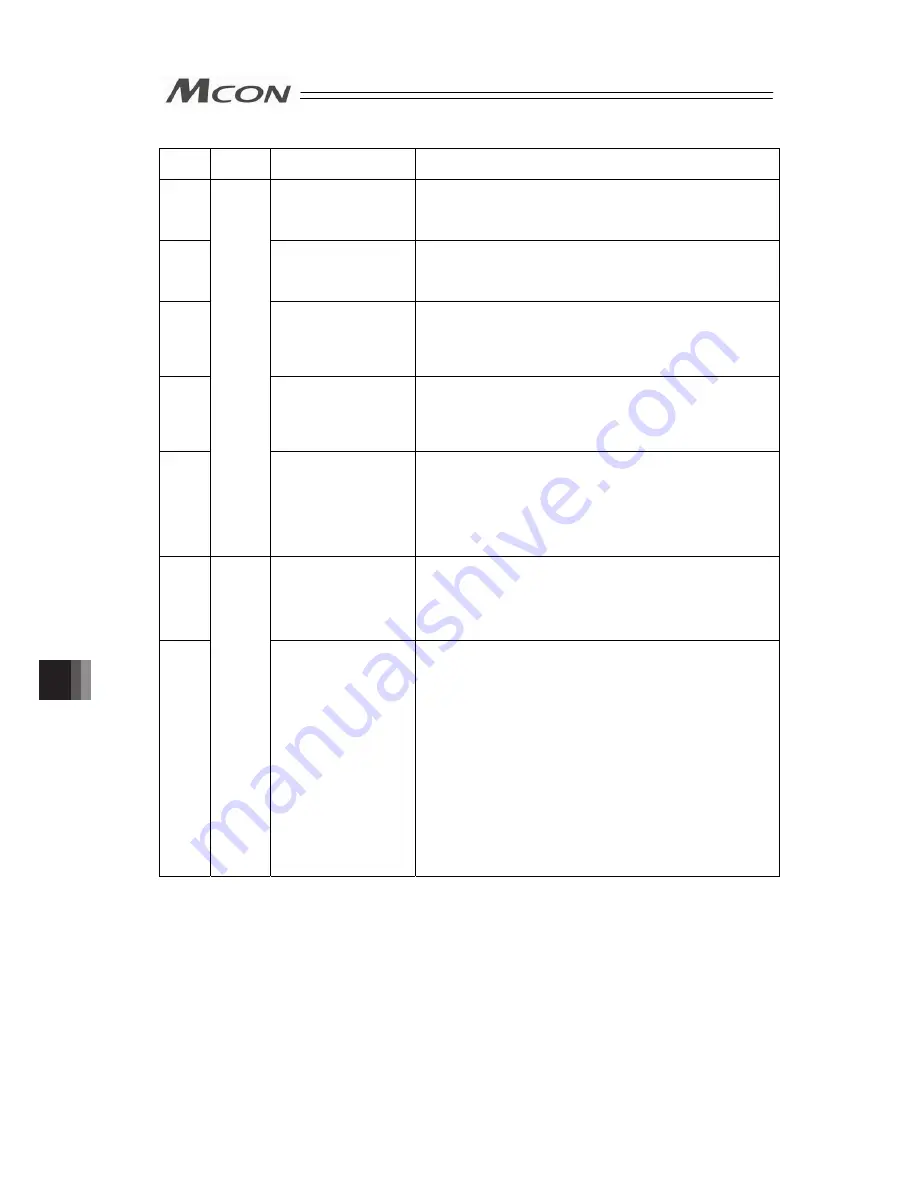

336

Alarm

Code

Alarm

Level

Alarm Name

Cause/Treatment

085

Position No. error during

movement

Cause

: A non-existing (invalid) position number was

specified in the positioner mode.

Treatment : Check the position table again and indicate an

effective position number.

090

Software reset command

in servo-ON condition

Cause

: A software reset command was issued when the

servo was ON.

Treatment : Issue a software reset command after confirming

that the servo is OFF (SV signal is 0).

091

Position No. error in

teaching

Cause

: The position number out of the available range was

selected in the teaching.

Treatment : Set the indication position number to 255 or less in

Positioner 1 or Positioner 2 Mode, or to 64 or less in

Remote I/O Teaching Mode.

092

PWRT signal detection

during movement

Cause

: The current position write signal PWRT was input in

the teaching mode of PIO pattern 1 while the

actuator was jogging.

Treatment : Check that JOG+/- signal is not on and stopped

(MOVE output signal is off) before inputting.

093

Operation

release

PWRT signal detection

in incomplete home

return

Cause

: The current position write signal PWRT was input in

the teaching mode of PIO pattern 1 when home

return was not yet completed.

Treatment : Input the HOME signal first to perform home return,

and then input the PWRT signal after confirming

that the home return has completed (HEND output

signal is ON).

0A0

PIO function assignment

error

Cause

: Data input in Parameter No. 25 PIO Pattern Select

is not appropriate.

Treatment : Select either of PIO Patterns 0, 1, 2, 4 or 5.

Select 6 when in a mode other than Remote I/O

Mode.

0A1

Cold start

Parameter data error

Cause

: The data input range in the parameter area is not

appropriate.

Example 1) This error occurs when the magnitude

relationship is apparently inappropriate

such as when 300mm was incorrectly

input as the value of the soft limit negative

side while the value of the soft limit

positive side was 200.3mm.

Example 2) In rotary axis, when the index mode is

changed to the normal mode and the soft

limit negative side is 0, this error is issued.

Set the soft limit negative side to a value

-0.3mm is added to the outer side of the

effective stroke. [Refer to 8.2 [2] Soft limit

+, Soft limit -]

Treatment : Change the value to the appropriate one.

Chapter 9

Troubleshooting

Summary of Contents for MCON-C

Page 1: ...MCON C CG Controller Instruction Manual Fourth Edition ...

Page 2: ......

Page 48: ...38 Chapter 1 Specifications Check ...

Page 268: ...258 3 10 Fieldbus Status LEDs ...

Page 274: ...264 Chapter 4 Vibration Suppress Control Function ...

Page 278: ...268 Chapter 5 Collision Detection Feature ...

Page 284: ...274 Chapter 6 Power saving Function ...

Page 292: ...282 Chapter 7 Absolute Reset and Absolute Battery ...

Page 358: ...348 Chapter 9 Troubleshooting ...

Page 474: ...Chapter 10 Appendix 464 ...

Page 478: ......

Page 479: ......