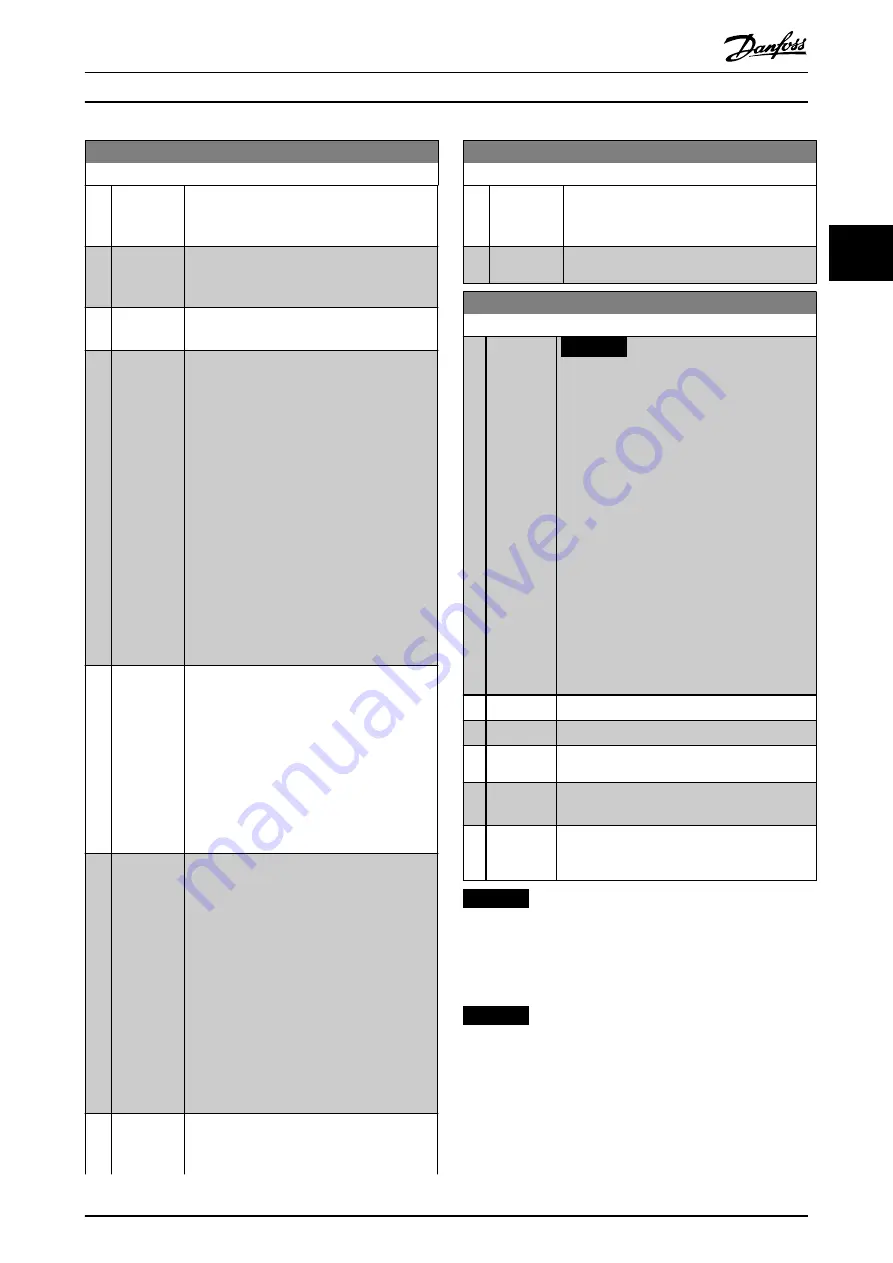

1-72 Start Function

Option:

Function:

[0] DC Hold/

delay time

Energizes motor with a DC hold current

(

parameter 2-00 DC Hold Current

) during the

start delay time.

[1] DC Brake/

delay time

Energizes motor with a DC brake current

(

parameter 2-01 DC Brake Current

) during the

start delay time.

[2]

*

Coast/delay

time

Motor coasted during the start delay time

(inverter off).

[3] Start speed

cw

Only possible with VVC

+

.

Connect the function described in

parameter 1-74 Start Speed [RPM]

and

in the start delay

time.

Regardless of the value applied by the

reference signal, the output speed applies the

setting of the start speed in

parameter 1-74 Start Speed [RPM]

or

parameter 1-75 Start Speed [Hz]

, and the

output current corresponds to the setting of

the start current in

. This function is typically used in

hoisting applications without counterweight

and especially in applications with a cone-

motor where the start is clockwise, followed

by rotation in the reference direction.

[4] Horizontal

operation

Only possible with VVC

+

.

For obtaining the function described in

parameter 1-74 Start Speed [RPM]

and

during the start

delay time. The motor rotates in the reference

direction. If the reference signal equals 0,

parameter 1-74 Start Speed [RPM]

is ignored

and the output speed equals 0. The output

current corresponds to the setting of the start

current in

.

[5] VVC+/Flux

clockwise

For the function described in

parameter 1-74 Start Speed [RPM]

only. The

start current is calculated automatically. This

function uses the start speed in the start delay

time only. Regardless of the value set by the

reference signal, the output speed equals the

setting of the start speed in

parameter 1-74 Start Speed [RPM]

.

[3] Start

speed/current clockwise

and

[5] VVC

+

/Flux

clockwise

are typically used in hoisting

applications.

[4] Start speed/current in reference

direction

is particularly used in applications

with counterweight and horizontal movement.

[6] Hoist Mech.

Brake Rel

For utilizing mechanical brake control

functions (

to

parameter 2-28 Gain Boost Factor

). This

1-72 Start Function

Option:

Function:

parameter is only active in flux control

principle, in a mode with motor feedback or

sensorless mode.

[7] VVC+/Flux

counter-cw

1-73 Flying Start

Option:

Function:

NOTICE

This parameter cannot be adjusted while

the motor is running.

This function makes it possible to catch a freely

spinning motor, for exmaple coasted because of

mains dropout.

When Flying start is enabled,

and

have no function.

When options

[1]

and

[2]

are enabled,

parameter 1-58 Flying Start Test Pulses Current

and

parameter 1-59 Flying Start Test Pulses

are used to specify conditions for

flying start.

Options

[3]

and

[4]

are set to search for the

motor in the reference direction only, which

allows a faster execution of the motor catch.

[0] Disabled

No function.

[1] Enabled

Enable after coast.

[2] Enabled

Always

Enable at every start.

[3] Enabled

Ref. Dir.

Enable after coast, search in reference direction

only.

[4] Enab.

Always Ref.

Dir.

Enable at every start, search in reference

direction only.

NOTICE

This function is not recommended for hoisting

applications.

For power levels above 55 kW, flux mode must be used

to achieve the best performance.

NOTICE

To obtain the best flying start performance, the

advanced motor data,

parameter 1-30 Stator Resistance

to

parameter 1-35 Main Reactance (Xh)

, must be

correct.

Parameter Descriptions

Programming Guide

MG33MP02

Danfoss A/S © 10/2018 All rights reserved.

59

3

3

Summary of Contents for VLT AutomationDrive FC 302

Page 2: ......