5 - 82

MELSEC-A

5 DATA USED FOR POSITIONING CONTROL

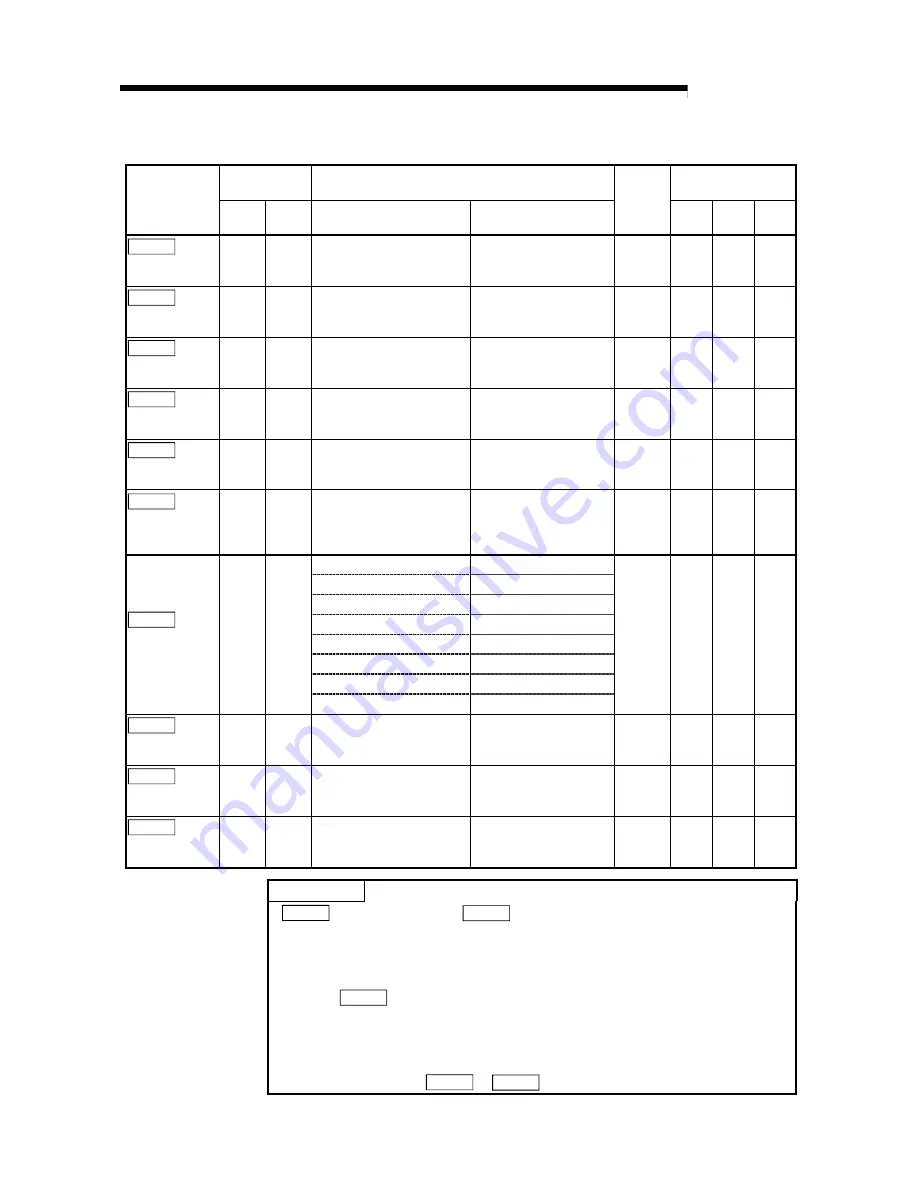

(2) Servo adjustment parameters

Servo amplifier

side parameter

Setting value, setting range

Setting value buffer

memory address

Item

No.

Abbre-

viation

Value set with peripheral

device

Value set with sequence

program

Default

value

Axis 1 Axis 2 Axis 3

Pr.112

Load inertia

ratio

No.12

GD2

0.0 to 100.0 (%)

0 to 1000 (0.1%)

30

112

262

412

Pr.113

Position loop

gain 1

No.13

PG1

4 to 1000 (rad/s)

4 to 1000 (rad/s)

70

113

263

413

Pr.114

Speed loop

gain 1

No.14

VG1

20 to 5000 (rad/s)

20 to 5000 (rad/s)

1200

114

264

414

Pr.115

Position loop

gain 2

No.15

PG2

1 to 500 (rad/s)

1 to 500 (rad/s)

25

115

265

415

Pr.116

Speed loop

gain 2

No.16

VG2

20 to 8000 (rad/s)

20 to 8000 (rad/s)

600

116

266

416

Pr.117

Speed

integral

compensation

No.17

VIC

1 to 1000 (ms)

1 to 1000 (ms)

20

117

267

417

0 : Not used

0

1 :

1125

1

2 :

563

2

3 :

375

3

4 :

282

4

5 :

225

5

6 :

188

6

Pr.118

Notch filter

selection

No.18 NCH

7 :

161

7

0

118 268 418

Pr.119

Feed forward

gain

No.19

FFC

0 to 100 (%)

0 to 100 (%)

0

119

269

419

Pr.120

In-position

range

No.20

INP

0 to 50000 (pulse)

0 to 50000 (pulse)

100

120

270

420

Pr.121

Solenoid

brake output

No.21

MBR

0 to 1000 (ms)

0 to 1000 (ms)

100

121

271

421

POINT

"

Pr.112

Load inertia ratio" to "

Pr.117

Speed integral compensation" are

transferred to the servo amplifier when the PLC CPU is powered ON or reset or the

PLC READY signal [Y1D] turns ON. When auto tuning is executed and operation is

performed, however, they are changed to the optimum values in the servo amplifier.

At this time, the auto tuning results are not reflected on the AD75.

Hence, if "

Pr.108

Auto tuning" is changed to "2: Invalid" and the PLC CPU is

powered ON or reset or the PLC READY signal [Y1D] is turned ON, the settings

return to the status before auto tuning, and the motor may vibrate.

When it is desired to save the optimum values obtained by auto tuning, set the data

read from the buffer memory addresses 858 to 863 (Axis 1), 958 to 963 (Axis 2),

1058 to 1063 (Axis 3) to

Pr.112

to

Pr.117

, and perform write to flash ROM.

Содержание A1SD75M1

Страница 2: ......

Страница 20: ...A 18 MEMO...

Страница 22: ...MEMO...

Страница 27: ...1 5 MELSEC A 1 PRODUCT OUTLINE MEMO...

Страница 42: ...1 20 MELSEC A 1 PRODUCT OUTLINE MEMO...

Страница 52: ...2 10 MELSEC A 2 SYSTEM CONFIGURATION MEMO...

Страница 111: ...5 21 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Страница 115: ...5 25 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Страница 123: ...5 33 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Страница 127: ...5 37 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Страница 167: ...5 77 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Страница 193: ...5 103 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Страница 276: ...5 186 MELSEC A 5 DATA USED FOR POSITIONING CONTROL MEMO...

Страница 332: ...7 18 MELSEC A 7 MEMORY CONFIGURATION AND DATA PROCESS MEMO...

Страница 334: ...MEMO...

Страница 422: ...9 64 MELSEC A 9 MAIN POSITIONING CONTROL MEMO...

Страница 446: ...10 24 MELSEC A 10 ADVANCED POSITIONING CONTROL MEMO...

Страница 472: ...11 26 MELSEC A 11 MANUAL CONTROL MEMO...

Страница 576: ...12 104 MELSEC A 12 CONTROL AUXILIARY FUNCTIONS MEMO...

Страница 673: ...Appendix 5 MELSEC A APPENDICES Axis address mm inch degree pulse Axis address mm inch degree pulse...

Страница 679: ...Appendix 11 MELSEC A APPENDICES Initial value Axis 1 Axis 2 Axis 3 Remarks 0 0 0 1 1 0 0 0 0 0 300 0 0 0...

Страница 683: ...Appendix 15 MELSEC A APPENDICES Initial value Axis 1 Axis 2 Axis 3 Remarks 0 0 1 0 0 50 80 0 0 980...

Страница 691: ...Appendix 23 MELSEC A APPENDICES Initial value Axis 1 Axis 2 Axis 3 Remarks 0 0 0 0 0 50 80 0 0 0 0 0 980 4000 0...

Страница 745: ......