Y axis w/reverse

scaling

Reads two 16-bit registers. Register #1 determines the state of the shape

displayed. Register #2 determines the position of the shape along the Y

axis. The OIT places the shape relative to the starting location using scaling

to calculate position. For example, if Input low=0, Input high=10, Scaling

low=0, and Scaling high=100, then when the value in the PLC register

increases by 1, the shape moves

up

along the Y axis by 10 pixels.

No. of states:

Range = 1 to 32

Input low:

This is the lowest raw data value that is in the PLC data register; Range =

-32767 to +32766

Input high:

This is the highest raw data value that is in the PLC data register; Range =

-32766 to +32767

Scaling low:

This is the low scaled value.

Scaling high:

This is the high scaled value.

5.

Refer to the Bit Lamp Object section for information on using the

Shape

tab.

6.

Refer to the Bit Lamp Object section for information on using the

Label

tab.

7.

Click

OK

. The Create Moving Shape Object form closes and the main screen of EasyBuilder

appears with the cursor tied to a rectangular outline of the part you just created at the upper

left corner of the screen. Move the part to the desired location on the window.

8.

Once the part is placed onto the window, you can adjust the location of the label inside the

part by clicking once on the label. This will highlight the entire object. Click on the label

again. Now only the label is highlighted, allowing you to move it without moving the part.

Note: if you double-click (click twice rapidly) then you will not highlight the label but rather

enter the Moving Shape Object’s Attribute dialog box.

The An i ma tion Ob ject

The Animation Object is very similar to the Moving Shape Object. It also allows you to create a shape or bitmap on

a screen that can change the way it looks as well as where it is located on the OIT screen depending upon the control

of the PLC. However, the Animation Object moves along a predefined path that is determined when you create the

part. Because of this, the Animation Object requires only two registers for changing state and X/Y movement:

·

the Animation object continuously reads a PLC register and displays the corresponding shape or bitmap that

is tagged to the number of states defined

·

the Animation object continuously reads a second PLC register to determine which position along the

predefined path it should be

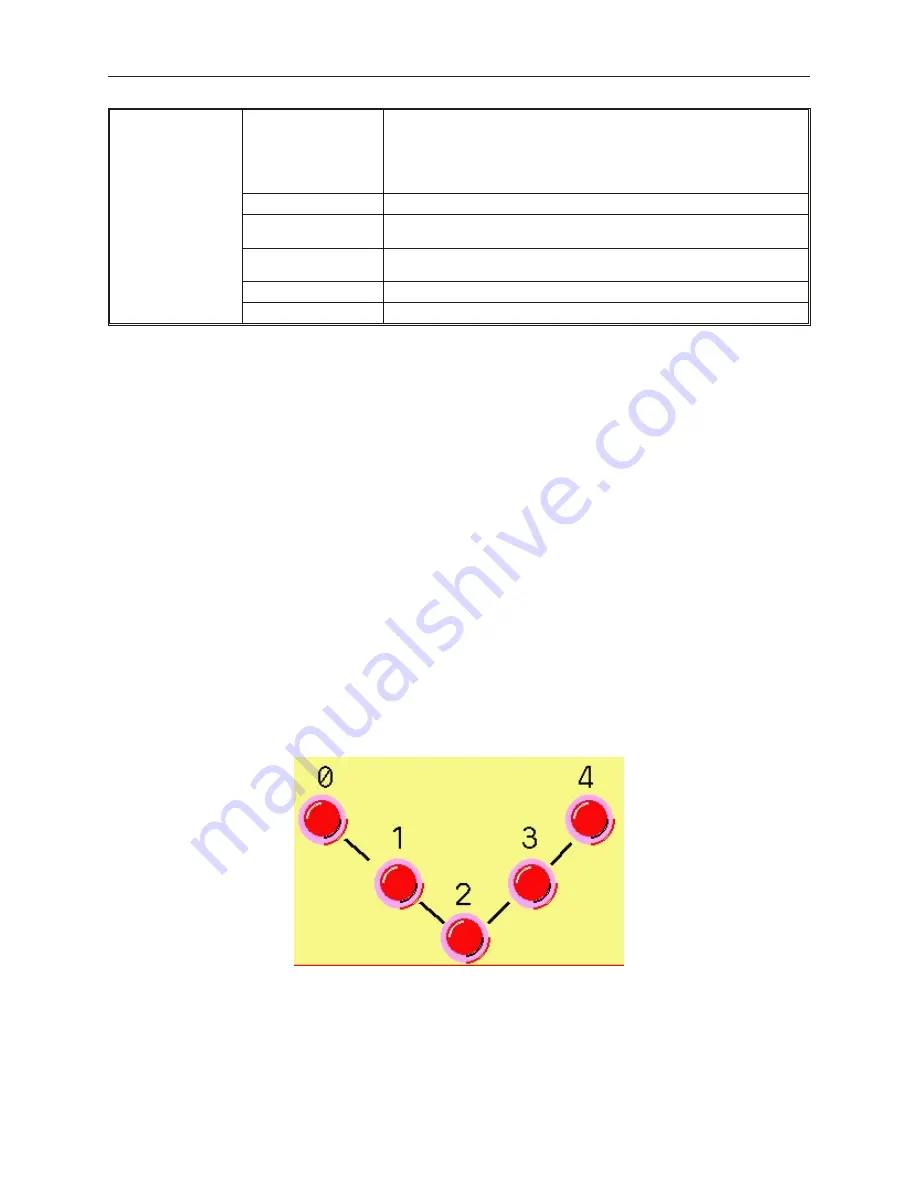

As shown in the following example, the part moves along a predefined track when the value in the second PLC

register is incremented:

1010-1001a, Rev 02

Rep re senting Data with Graph ics Ob jects

197

Содержание Silver HMI504T

Страница 1: ...1010 1001A Rev 02...

Страница 20: ...1010 1001a Rev 02 16 Silver Series Installation Operation Manual OIT to PC Serial Port Pin Assignments...

Страница 32: ...1010 1001a Rev 02 28 Silver Series Installation Operation Manual...

Страница 128: ...1010 1001a Rev 01 124 Silver Series Installation Operation Manual...

Страница 156: ...1010 1001a Rev 02 152 Silver Series Installation Operation Manual...

Страница 166: ...1010 1001a Rev 02 162 Silver Series Installation Operation Manual...

Страница 216: ...1010 1001a Rev 01 212 Silver Series Installation Operation Manual...

Страница 251: ...1010 1001a Rev 02 Macros 247 Set Bit Objects Attributes Dialog Project Example of Add 2...

Страница 264: ...End Macro_Command 1010 1001a Rev 02 260 Silver Series Installation Operation Manual...

Страница 268: ...1010 1001a Rev 01 264 Silver Series Installation Operation Manual...