EXPERT Standard Series User Manual

90

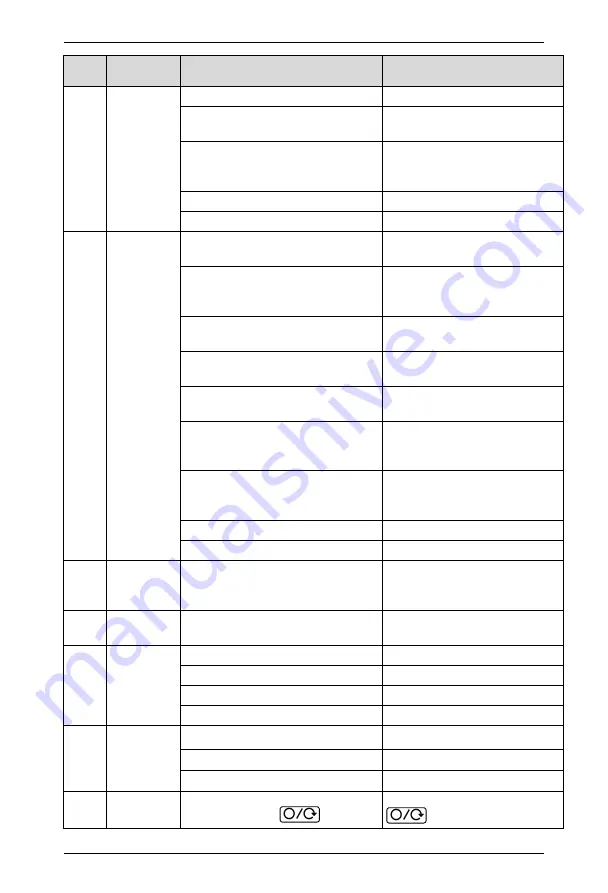

Fault

Code Fault Type

Possible Fault Reasons

Countermeasures

time.

V/F curve is not suitable

Adjust V/F curve and torque

lifting

When instant stop occurs,

implement restart on all rotating

motors.

Set start method F2.00 as the

rotational speed tracking

restart function.

Power grid voltage is too low.

Check power grid voltage

Load is too large

Select drive of larger power

E010

IGBT

module

protection

Instant overcurrent of the drive

See overcurrent

countermeasures

Output three-phase has interface

short circuit

Or grounding short circuit.

Re-wiring.

Tunnel blocked or fan damaged. Smoothen the tunnel or

change the fan.

Ambient temperature is too high. Reduce ambient

temperature.

Control panel wiring or inserts

are loose.

Check and connect again.

Current waveform abnormal

caused by reasons such as

output phase fault etc.

Check wiring.

Auxiliary power supply is

damaged, and driving voltage is

undervoltage.

Seek for services

Drive module shoot-through

Seek for services

Control panel abnormal

Seek for services

E011 Input phase

loss

Phase fault for input R, S and T

Check installation

assembling line

Check input voltage

E012 Output

phase loss

Phase fault for output U, V and

W

Check output wiring

Check motor and cable

E013

Overheat of

IGBT

radiator

Ambient temperature is too high Reduce ambient temperature

Tunnel is blocked

Clean the tunnel

Fan is damaged

Change the fan

Drive module is abnormal

Seek for services

E014

Overheat of

rectification

module

radiator

Ambient temperature is too high Reduce ambient temperature

Tunnel is blocked

Clean the tunnel

Fan is damaged

Change the fan

E015 External

failure

In non-operation panel mode,

use emergency

key.

View function definition of

key in FC.31.