EXPERT Standard Series User Manual

159

Note:

1. Given can also be the digital given and serial port given of the operation panel.

2. The two-phase input pulse helps to improve speed detection precision, and the

single-phase pulse input wiring is concise.

3. The two-phase pulse input can only adopt orthogonal mode.

4. If the drive te24 is used to supply power to the encoder, in this case, the

maximum load current of the optical encoder shall be ≤200mA.

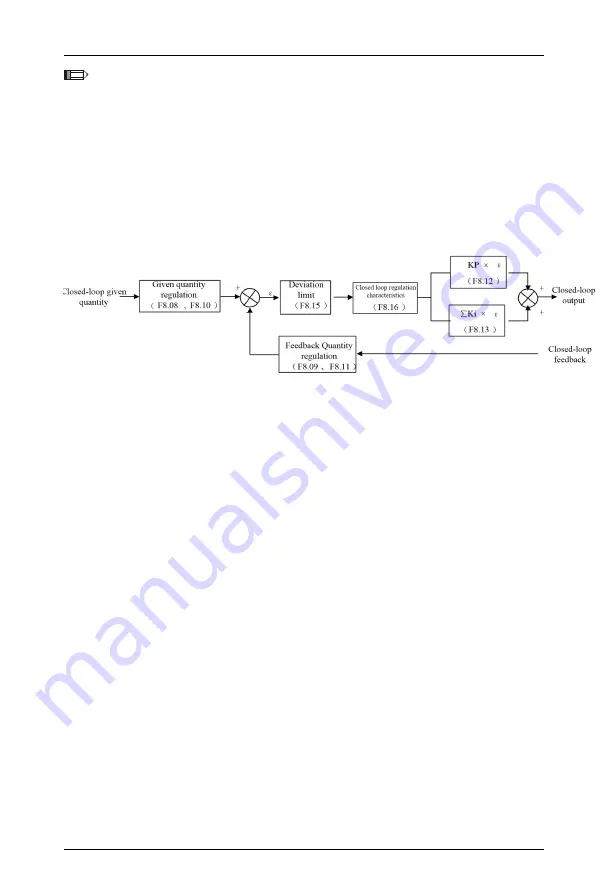

The working principle block diagram of the drive built-in PID is shown in Figure 6-38:

Figure 6-38 PI Principle Block Diagram

In the above figure, KP: Proportional gain; KI: Integral gain

In Figure 6-38, the definitions of closed-loop given quantity, feedback quantity,

deviation limit and proportional integral parameters are the same as the meanings of

ordinary PI adjustments, see the definitions in F8.01~F8.15.

The drive built-in PI has two characteristics as follows:

The relationship between the given quantity and the corresponding expected feedback

quantity is defined by F8.08~F8.11.

For example, in Figure 6-39, when the given quantity is an analog signal of 0~10 V, the

expected corresponding controlled quantity is 0~1 MPa, and the corresponding pressure

sensor signal is 4~20 mA. The relationship between the given quantity and the expected

feedback quantity is shown in Figure 6-39.