EXPERT Standard Series User Manual

89

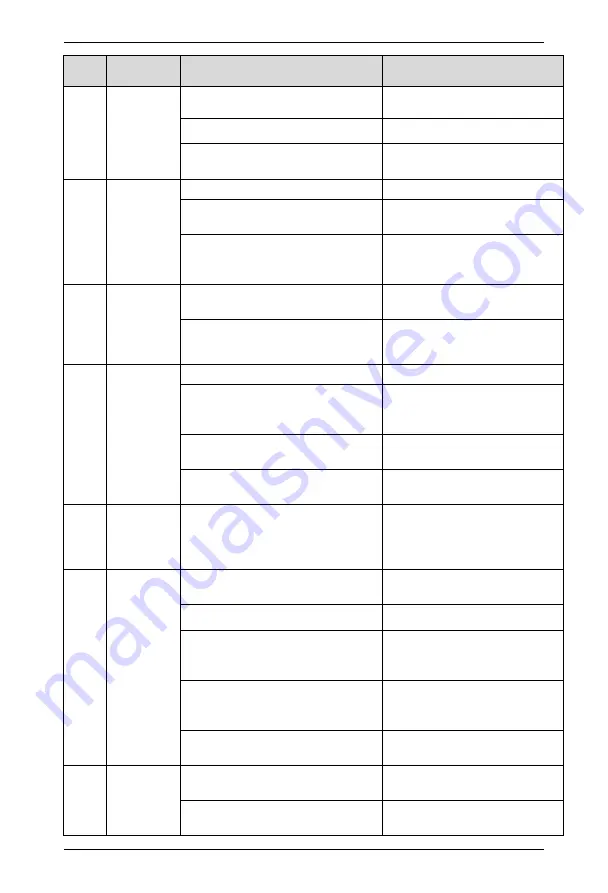

Fault

Code Fault Type

Possible Fault Reasons

Countermeasures

operation Load abnormal

Carry out load check.

Power grid voltage is low

Check input power supply

Drive power is low

Select the drive of large

power level

E004

Over

voltage

during

acceleratin

g operation

Input voltage abnormal

Check input power supply

Accelerating time is set too short Properly lengthen the

accelerating time

When instant stop occurs,

implement restart on all rotating

motors.

Set start method F2.00 as the

rotational speed tracking

restart function.

E005

Over

voltage

during

deceleratin

g operation

Decelerating time is too short

(relative to regenerated energy)

Lengthen the decelerating

time

There’s potential load or load

inertia torque is large.

Select proper energy

consumption braking parts.

E006

Over

voltage

during

constant

speed

operation

Input voltage abnormal

Check input power supply

Accelerating and decelerating

time is set too short.

Properly lengthen the

accelerating and decelerating

time

Abnormal change occurred in

input voltage.

Install input reactor.

Load has large inertia.

Consider to adopt energy

consumption braking parts.

E007

Under

voltage

during

running

Abnormal input voltage

Examine supply voltage

E008 Motor

overload

V/F curve not suitable

Correctly set V/F curve and

torque lifting.

Power grid voltage is too low.

Check power grid voltage

General motor is under long-term

low speed running with huge

load.

Special motor could be

selected for long-term low

speed running.

Motor overload protection

coefficient is set incorrectly.

Correctly set the motor

overload protection

coefficient

Motor blocked or sudden change

in load is too large.

Check load.

E009 Drive

overload

Accelerating time is too short.

Lengthen the accelerating

time

DC braking amount is too large. Decrease DC braking

current, and lengthen braking