Engine Description

Teledyne Continental Motors, Inc.

TM

2-26

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

2-2.6.2. Fuel Injector Nozzles

Three Electronic Control Units (ECU) meter the fuel to individual cylinders. The ECU

monitors changes in air density and engine speed to determine how much fuel will be

injected into the intake port of the cylinder.

The fuel distribution block distributes fuel to each of the fuel injector nozzles. ECUs

constantly monitored the fuel pressure using dual redundant fuel pressure sensors

mounted on the fuel distribution block.

The FADEC System controls the fuel supplied to each cylinder using solenoid-actuated

sequential port fuel injectors. A fuel injector assembly is located in each cylinder head,

one fuel injector per cylinder. The fuel injector is threaded on both ends; outlet screws

into the tapped fuel injector boss in the cylinder head.

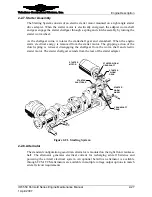

The fuel injector assembly is made up of two parts: the control coil and the injector

nozzle (Figure 2-20). The internal components of the fuel injector nozzle consist of a

pintle valve and a spring. The solenoid creates an electromagnetic field to lift the pintle

valve and open the path for fuel to flow. The solenoid coil fits over the pintle valve body

and is held in place with a jam nut that threads onto the valve body. When electrical

current ceases to flow through the solenoid, the spring force closes the pintle valve and

shuts off the fuel flow to the fuel injector. The valve design and injector end form a self-

atomizing feed.

WASHER

INJECTOR BODY

SOLENOID COIL

LEAD WIRE

FUEL LINE

RETAINING NUT

TIE STRAP

SUPPORT

WASHER

INJECTOR BODY

SOLENOID COIL

LEAD WIRE

FUEL LINE

RETAINING NUT

TIE STRAP

SUPPORT

Figure 2-20.

FADEC Fuel Injector and Solenoid