Teledyne Continental Motors, Inc.

TM

Troubleshooting

Fuel

Injection Operational

Check, cont.

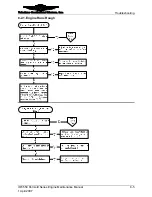

Set SSA Simulator Switches:

Engine ……………………..TCM

Cylinders ……………………....6

Speed………………....Midrange

Power………………………..ON

Purge fuel lines for one minute.

Power……………..………..OFF

Empty catch cans and return catch cans to the

tubing ends.

Power……………………….ON

Collect fuel for one minute

Power………………………OFF

Ignition Switch…………….OFF

Pour contents of each catch can contents in to a

burette or other precisely graduated container.

Record the volume of each catch can for

comparison. Variation between injectors should not

exceed 3%. Discard fuel waste.

Replace faulty injector

(Sect. 10-6). Repeat Fuel

Injector Operational Check.

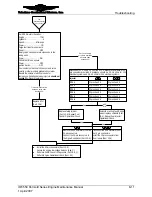

Disconnect P1, P2 and P3 from the ECUs. Measure resistance at 50-

pin connector pins listed. Resistance should be 2.3-2.6 ohms for 12V

electrical systems and 5.6-5.9 ohms for 24V electrical systems.

N P R

Injector

B C

P1 pins 3 and 4

CYL 1

P1 pins 3 and 4

P1 pins 5 and 6

CYL 2

P1 pins 5 and 6

P2 pins 3 and 4

CYL 3

P2 pins 3 and 4

P2 pins 5 and 6

CYL 4

P2 pins 5 and 6

P3 pins 3 and 4

CYL 5

P3 pins 3 and 4

P3 pins 5 and 6

CYL 6

P3 pins 5 and 6

Replace ECU

(Sect. 10-6).

Flow normal-deviation

between catch cans

less than 3%

Catch can empty

or volume deviation

between cans

exceeds 3%

Solenoid or wiring fault. Repair

wire or replace solenoid (Sect.

10-5). Repeat Fuel Injector

Operational Check.

OK

NOT

OK

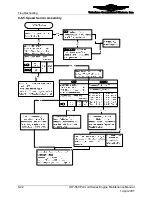

Install the 50-pin connectors (Sect. 10-6)

Secure the engine low voltage harness (App. C)

Perform a FADEC Level I Diagnostics ( Sect. 8-6.1)

Perform Engine Operational Check (Sect. 6-1)

Remove the SSA simulator from the

25-pin connectors.

Connect the 25-pin connectors to

the Signal Conditioner (Sect. 10-6).

B

C

Disconnect the SSA Simulator from

the 13 pin connectors.

Install the 13-pin connectors from

the oil sump (Sect. 10-6).

N

P

R

OK

OK

IOF-550 Permold Series Engine Maintenance Manual

8-11

1 April 2007