Non-Overhaul Removal and Replacement

Teledyne Continental Motors, Inc.

TM

10-8

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

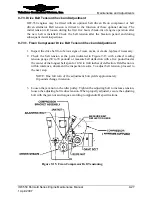

Figure 10-1.

Fuel Pump Drive Coupling Fits & Limits

Table 10-4.

Fuel Pump Drive Coupling Fits & Limits

Ref.

Part

Service Limits Across

Flats (diameter in inches)

No.

Minimum

Maximum

1. Fuel pump drive coupling to crankshaft gear clearance

0.0095L

0.0155L

2. Fuel pump drive coupling to fuel pump clearance:

0.0030L

0.0090L

T= Tight L=Loose

10-3.

Starter Motor and Adapter Replacement

Repair or replace the starter motor if it will not turn the starter adapter. Repair the starter

motor in accordance with the TCM Starter Service Instructions (X30592 or STR-1). If the

starter motor is beyond repair, replace it with a serviceable starter.

Replace the starter adapter if starter motor turns but the starter adapter does not engage

the engine or the starter adapter is malfunctioning.

10-3.1. Starter Motor Removal

Procedure

WARNING

If all power is not disconnected, a loose or broken wire could

allow the engine to start and the propeller to rotate. Do not

stand or place equipment within the arc of the propeller.

1.

Disconnect engine electrical power; turn the Master Power Switch and Ignition

Switch to the OFF position.

2.

Disconnect the aircraft battery and electrical cable from the starter motor according to

the airframe manufacturer’s instructions.

3.

Remove the two nuts and plain washers from the starter motor mounting studs

(Figure 10-2).