Teledyne Continental Motors, Inc.

TM

Non-Overhaul Removal and Replacement

IOF-550 Permold Series Engine Maintenance Manual

10-107

1 April 2007

7.

When the idler sheave is properly adjusted, torque the sheave screw per Appendix B

of this manual.

8.

Lubricate the sheave 12-point, self- locking nut with clean aviation engine oil.

9.

Torque this sheave nut per Appendix B while keeping the engine held securely in

position to prevent it from turning.

CAUTION: Prevent the engine from turning when torquing the nut.

10.

Verify all threads of the sheave nut are engaged.

Figure 10-82.

Sheave Alignment

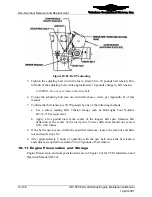

10-10.2. Compressor Drive Belt Installation and Tension Adjustment

Procedure

1.

Loosen the jam nut (Figure 10-83) holding the adjusting bolt and slide nut in place.

Loosen the jam nut just enough to allow the slide nut to move freely.

2.

Inspect the new drive belt. Ensure the belt material is supple and is free of cracks and

deformities.

3.

Loosen the adjusting bolt enough to ease the new belt over the sheave and install the

new belt on the drive sheave.

4.

Slide the idler pulley snugly against the belt and tighten the adjusting bolt finger tight

into the socket. The idler sheave should turn by hand with little resistance under the

load of the belt.