Maintenance and Adjustments

Teledyne Continental Motors, Inc.

TM

9-22

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

CAUTION: Connections requiring torqued fasteners must not

exhibit movement or motion between components. Excessive

movement may cause abnormal wear resulting in component

malfunction or failure and subsequent loss of power.

3.

Check torqued fasteners for secure, unrestricted movement. If necessary, adjust

torque according to Appendix B values.

4.

After cleaning, dry parts with compressed air.

5.

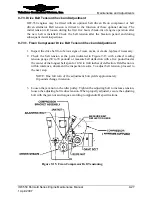

Unless otherwise specified apply LPS 2, PERMATEX “Maintain” Lubricant (or

equivalent) to the pivot point (Figure 9-11). If the lever or linkages are replaced,

lubricate with SHELL # 5, LUBRIPLATE #630AA(or equivalent) during installation.

6.

Maintain other pivot points and control connections in accordance with the aircraft

manufacturer's instructions.

WARNING

Anytime throttle linkage, attaching hardware or levers have

been replaced or reassembled, check, adjust (as needed) and

check the operation of the fuel injection system.

7.

Comply with the airframe manufacturer and/or their most current published

instructions concerning aircraft engine control cable attach point inspection, cleaning,

repair, installation and lubrication.

8.

After cleaning and lubrication, verify each control has full limit of travel, the required

safeties are in place, and no binding of levers or linkages is occurring.

9.

If all maintenance is complete, perform the Operational Checks specified in Chapter

6, Operational Performance Checks.

IOF-550 B&C Throttle Body

IOF-550 N, P & R Throttle Body

Figure 9-11.

Throttle and Fuel Control Lubrication