Non-Overhaul Removal and Replacement

Teledyne Continental Motors, Inc.

TM

10-72

IOF-550 Permold Series Engine Maintenance Manual

1 April 2007

10-8.2. IOF-550-B & C Cylinder Removal

Procedure

1.

Disconnect the ignition harness from the spark plugs and remove the spark plugs

from the cylinder according to instructions in Chapter 9.

2.

Remove the CHT Sensor according to instructions in Section 10-6.21.

3.

Remove the Fuel Injection Solenoid and the Fuel Injector from the cylinder according

to instructions in Section 10-6.10.

4.

Remove the Induction and Exhaust System components in accordance with

instructions in Chapter 6, Engine Disassembly in the TCM Overhaul Manual (OH-24)

and any applicable airframe manufacturer’s instructions.

5.

Remove the Valve Train according to instructions in Section 10-8.1, “IOF-550-B & C

Valve Train Removal.”

6.

Remove the hydraulic tappets and pushrod tubes according to instructions in Section

10-8.11.

7.

While removing an engine cylinder, inspect components for wear and conformance to

dimensional criteria. Replace any worn component or component out of tolerance

based on the following criteria:

a.

Only allow parts that fall within the tolerance of the

service limits

in to remain in

service or be re-used.

b.

If a part has reached a service limit tolerance, it must be replaced with a part that

conforms to the specified service limits.

8.

Ensure the piston in the cylinder to be removed is at top dead center.

9.

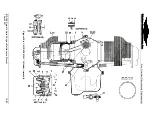

Using the appropriate wrenches, carefully remove the flange nuts (Figure 10-59) (40,

41, & 44) from the cylinder base flange and seventh stud locations.

10.

As the last several pieces of fastening hardware are being removed, cradle the

cylinder in your arm to support the cylinder. Note that the piston within the cylinder

can fall down if care is not used in subsequent steps where the cylinder will be

withdrawn.

11.

Remove the 7

th

stud brackets (42 & 43).

12.

While supporting the cylinder, carefully and slowly pull the cylinder outward in a

straight plane while keeping your other hand free to catch the piston as the cylinder is

withdrawn to prevent damage to the crankcase.

13.

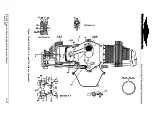

Remove the cylinder base O-ring (25). Install the old O-ring in a figure 8 pattern to

support the connecting rod- refer to Figure 10-60.

14.

Remove the piston pin (53) (Figure 10-59) and piston (48) from the connecting rod.