Teledyne Continental Motors, Inc.

TM

Engine

Description

IOF-550 Permold Series Engine Maintenance Manual

2-25

1 April 2007

2-2.6.1. Fuel Pump

Fuel enters the fuel pump at the top of the vapor separator swirl chamber where it is

centrifuged, separating the liquid from any fuel vapors. The liquid fuel is directed to the

fuel pump inlet vanes. The fuel pump vanes create the necessary differential pressure

required to draw fuel into the pump inlet and expel pressurized fuel from the pump outlet.

Fuel vapor is separated in the swirl chamber and is returned to the aircraft’s fuel tank.

From the fuel pump outlet, fuel travels through various fittings and fuel lines to the fuel

distribution block and fuel injector nozzles.

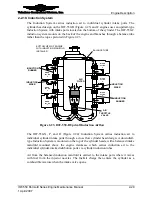

The positive displacement, engine-driven fuel pump varies the amount of fuel delivered

to the manifold in proportion with engine speed changes. The fuel pump is sized to

provide greater capacity than the engine requires. An integral aneroid valve functions to

increase pump output pressure during high manifold pressure operation. This

combination of mechanical control ensures proper pump pressure and delivery for all

engine operating speeds.

A check valve is provided to allow the aircraft boost pump pressure to bypass the engine

driven fuel pump during engine priming and starting. The check valve also permits the

use of an aircraft auxiliary fuel boost pump.

Figure 2-19.

Fuel Pump