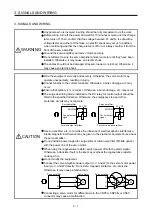

3. SIGNALS AND WIRING

3 - 2

POINT

When you use a linear servo motor, replace the following left words to the right

words.

Load to motor inertia ratio

→

Load to motor mass ratio

Torque

→

thrust

(Servo motor) Speed

→

(Linear servo motor) Speed

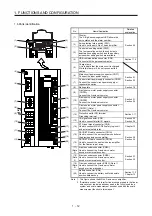

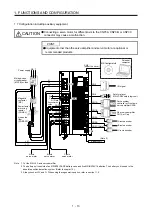

3.1 Input power supply circuit

CAUTION

Always connect a magnetic contactor between the power supply and the main

circuit power supply (L1, L2, and L3) of the servo amplifier, in order to configure a

circuit that shuts down the power supply on the side of the servo amplifier’s power

supply. If a magnetic contactor is not connected, continuous flow of a large

current may cause a fire when the servo amplifier malfunctions.

When alarms are occurring in all axes of A, B, and C, shut off the main circuit

power supply. Not doing so may cause a fire when a regenerative transistor

malfunctions or the like may overheat the regenerative resistor.

Check the servo amplifier model, and then input proper voltage to the servo

amplifier power supply. If input voltage exceeds the upper limit, the servo amplifier

will break down.

The servo amplifier has a built-in surge absorber (varistor) to reduce noise and to

suppress lightning surge. The varistor can break down due to its aged

deterioration. To prevent a fire, use a molded-case circuit breaker or fuse for input

power supply.

Connecting a servo motor for different axis to the CNP3A, CNP3B, or CN3C

connector may cause a malfunction.

The N- terminal is not a neutral point of the power supply. Incorrect wiring will

cause a burst, damage, etc.

POINT

Even if alarm has occurred, do not switch off the control circuit power supply.

When the control circuit power supply has been switched off, optical module

does not operate, and optical transmission of SSCNET III/H communication is

interrupted. Therefore, the next axis servo amplifier displays "AA" at the

indicator and turns into base circuit shut-off. The servo motor stops with starting

dynamic brake.

EM2 has the same device as EM1 in the torque control mode.

Connect the 1-phase 200 V AC to 240 V AC power supply to L1 and L3. One of

the connecting destinations is different from MR-J3W Series Servo Amplifier.

When using MR-J4W as a replacement for MR-J3W, be careful not to connect

the power to L2.

Configure the wiring so that the main circuit power supply is shut off and the servo-on command turned off

after deceleration to a stop due to an alarm occurring, an enabled servo forced stop, or an enabled controller

forced stop. A molded-case circuit breaker (MCCB) must be used with the input cables of the main circuit

power supply.

Summary of Contents for MR-J4W2

Page 9: ...A 8 MEMO ...

Page 17: ...8 MEMO ...

Page 31: ...1 FUNCTIONS AND CONFIGURATION 1 14 MEMO ...

Page 95: ...4 STARTUP 4 20 MEMO ...

Page 169: ...6 NORMAL GAIN ADJUSTMENT 6 20 MEMO ...

Page 201: ...7 SPECIAL ADJUSTMENT FUNCTIONS 7 32 MEMO ...

Page 213: ...8 TROUBLESHOOTING 8 12 MEMO ...

Page 219: ...9 OUTLINE DRAWINGS 9 6 MEMO ...

Page 229: ...10 CHARACTERISTICS 10 10 MEMO ...

Page 295: ...13 USING STO FUNCTION 13 14 MEMO ...

Page 327: ...14 USING A LINEAR SERVO MOTOR 14 32 MEMO ...

Page 371: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Page 521: ...APPENDIX App 38 ...

Page 537: ...MEMO ...

Page 541: ......