16. FULLY CLOSED LOOP SYSTEM

16 - 17

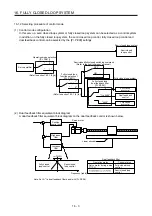

16.3.3 Operation from controller

The fully closed loop control compatible servo amplifier can be used with any of the following controllers.

Category Model

Remark

Motion controller

R_MTCPU/Q17_DSCPU

Speed control (II) instructions (VVF and VVR) cannot

be used.

Simple motion module

RD77MS_/QD77MS_

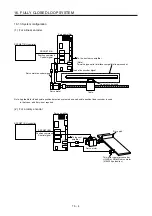

An absolute type linear encoder is necessary to configure an absolute position detection system under fully

closed loop control using a linear encoder. In this case, the encoder battery need not be installed to the

servo amplifier. When an rotary encoder is used, an absolute position detection system can be configured by

installing the encoder battery to the servo amplifier. In this case, the battery life will be shorter because the

power consumption is increased as the power is supplied to the two encoders of motor side and load side.

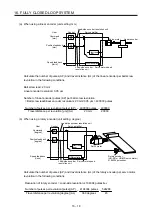

(1) Operation from controller

Positioning operation from the controller is basically performed like the semi closed loop control.

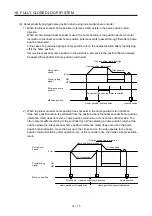

(2) Servo system controller setting

When using fully closed loop system, make the following setting.

[Pr. PA01], [Pr. PC17], [Pr. PE01], [Pr. PE03] to [Pr. PE05], [Pr. PE34] and [Pr. PE35] are written to the

servo amplifier and then are enabled using any of the methods indicated by

○

in Parameter enabled

conditions. [Pr. PE06] to [Pr. PE08] are enabled at setting regardless of the valid conditions.

Setting item

Parameter enabled

conditions

Settings

Controller

reset

Power

supply

Off

→

on

Motion

controller

R_MTCPU/

Q17_DSCPU

Simple motion

module

RD77MS_/

QD77MS_

Command

resolution

Load-side encoder resolution

unit

Servo

parameter

MR-J4-B fully closed loop servo amplifier setting

MR-J4-B fully closed loop control

Motor setting

Automatic setting

Home position setting condition selection ([Pr. PC17])

Set the items as required.

Fully closed loop selection ([Pr. PA01] and [Pr. PE01])

Fully closed loop selection 2 ([Pr. PE03])

Fully closed loop control error detection speed deviation

error detection level

([Pr. PE06])

Enabled at setting

regardless of the

enabled conditions

Fully closed loop control error detection position

deviation error detection level

([Pr. PE07])

Fully closed loop electronic gear numerator ([Pr. PE04]

and [Pr. PE34])

Fully closed loop electronic gear denominator ([Pr. PE05]

and [Pr. PE35])

Fully closed loop dual feedback filter ([Pr. PE08])

Enabled at setting

regardless of the

enabled conditions

Positioning

control

parameter

Unit setting

mm/inch/degree/pulse

Number of pulses per revolution (AP)

Travel distance per revolution (AL)

For the setting methods, refer to (2) (a), (b) in this section.

Summary of Contents for MR-J4W2

Page 9: ...A 8 MEMO ...

Page 17: ...8 MEMO ...

Page 31: ...1 FUNCTIONS AND CONFIGURATION 1 14 MEMO ...

Page 95: ...4 STARTUP 4 20 MEMO ...

Page 169: ...6 NORMAL GAIN ADJUSTMENT 6 20 MEMO ...

Page 201: ...7 SPECIAL ADJUSTMENT FUNCTIONS 7 32 MEMO ...

Page 213: ...8 TROUBLESHOOTING 8 12 MEMO ...

Page 219: ...9 OUTLINE DRAWINGS 9 6 MEMO ...

Page 229: ...10 CHARACTERISTICS 10 10 MEMO ...

Page 295: ...13 USING STO FUNCTION 13 14 MEMO ...

Page 327: ...14 USING A LINEAR SERVO MOTOR 14 32 MEMO ...

Page 371: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Page 521: ...APPENDIX App 38 ...

Page 537: ...MEMO ...

Page 541: ......