2. INSTALLATION

2 - 6

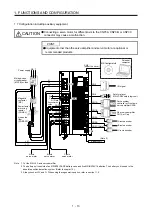

(3) Check that the connector is securely connected to the servo amplifier.

(4) Check that the wires are not coming out from the connector.

(5) Check for dust accumulation on the servo amplifier.

(6) Check for unusual noise generated from the servo amplifier.

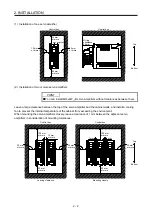

2.6 Parts having service lives

Service lives of the following parts are listed below. However, the service lives vary depending on operating

methods and environmental conditions. If any fault is found in the parts, they must be replaced immediately

regardless of their service lives.

For parts replacement, please contact your sales representative.

Part name

Life guideline

Smoothing capacitor

10 years

Relay

Number of power-on, forced stop by EM1 (Forced

stop 1), and controller forced stop times: 100,000

times

Number of on and off for STO: 1,000,000 times

Cooling fan

50,000 hours to 70,000 hours (7 to 8 years)

Absolute position battery

Refer to section 12.2.

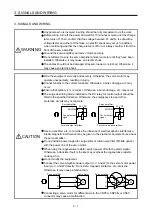

(1) Smoothing capacitor

Affected by ripple currents, etc. and deteriorates in characteristic. The life of the capacitor greatly

depends on ambient temperature and operating conditions. The capacitor will reach the end of its life in

10 years of continuous operation in normal air-conditioned environment (40

˚

C) surrounding air

temperature or less).

(2) Relays

Contact faults will occur due to contact wear arisen from switching currents. Relays reach the end of

their lives when the power has been turned on, forced stop by EM1 (Forced stop 1) has occurred, and

controller forced stop has occurred 100,000 times in total, or when the STO has been turned on and off

1,000,000 times while the servo motor is stopped under servo-off state. However, the lives of relays may

depend on the power supply capacity.

(3) Servo amplifier cooling fan

The cooling fan bearings reach the end of their life in 50,000 hours to 70,000 hours. Normally, therefore,

the fan must be changed in seven or eight years of continuous operation as a guideline.

It must also be changed if unusual noise or vibration is found during inspection.

The life is under the environment where a yearly average ambient temperature of 40

˚

C, free from

corrosive gas, flammable gas, oil mist, dust and dirt.

Summary of Contents for MR-J4W2

Page 9: ...A 8 MEMO ...

Page 17: ...8 MEMO ...

Page 31: ...1 FUNCTIONS AND CONFIGURATION 1 14 MEMO ...

Page 95: ...4 STARTUP 4 20 MEMO ...

Page 169: ...6 NORMAL GAIN ADJUSTMENT 6 20 MEMO ...

Page 201: ...7 SPECIAL ADJUSTMENT FUNCTIONS 7 32 MEMO ...

Page 213: ...8 TROUBLESHOOTING 8 12 MEMO ...

Page 219: ...9 OUTLINE DRAWINGS 9 6 MEMO ...

Page 229: ...10 CHARACTERISTICS 10 10 MEMO ...

Page 295: ...13 USING STO FUNCTION 13 14 MEMO ...

Page 327: ...14 USING A LINEAR SERVO MOTOR 14 32 MEMO ...

Page 371: ...16 FULLY CLOSED LOOP SYSTEM 16 24 MEMO ...

Page 521: ...APPENDIX App 38 ...

Page 537: ...MEMO ...

Page 541: ......