Chapter 15 DRYPRO 832 Utility Tool

15-16

15.7 Logo Setup

The logo mark output to the film can be set.

Logo data

Logo data that meets the following requirements must be prepared beforehand and saved to Printlink5-IN.

Logo output position

Logo mark is output to

“15.3 Print Condition (Page 15-9)”

in

“

Printing positions of logo, patient information,

and stamp characters (Page 15-11)”

.

1

Refer to

“15.1 DRYPRO 832 Utility Tool Start (Page 15-2)”

, and open the maintenance menu

window of the DRYPRO 832 Utility Tool.

2

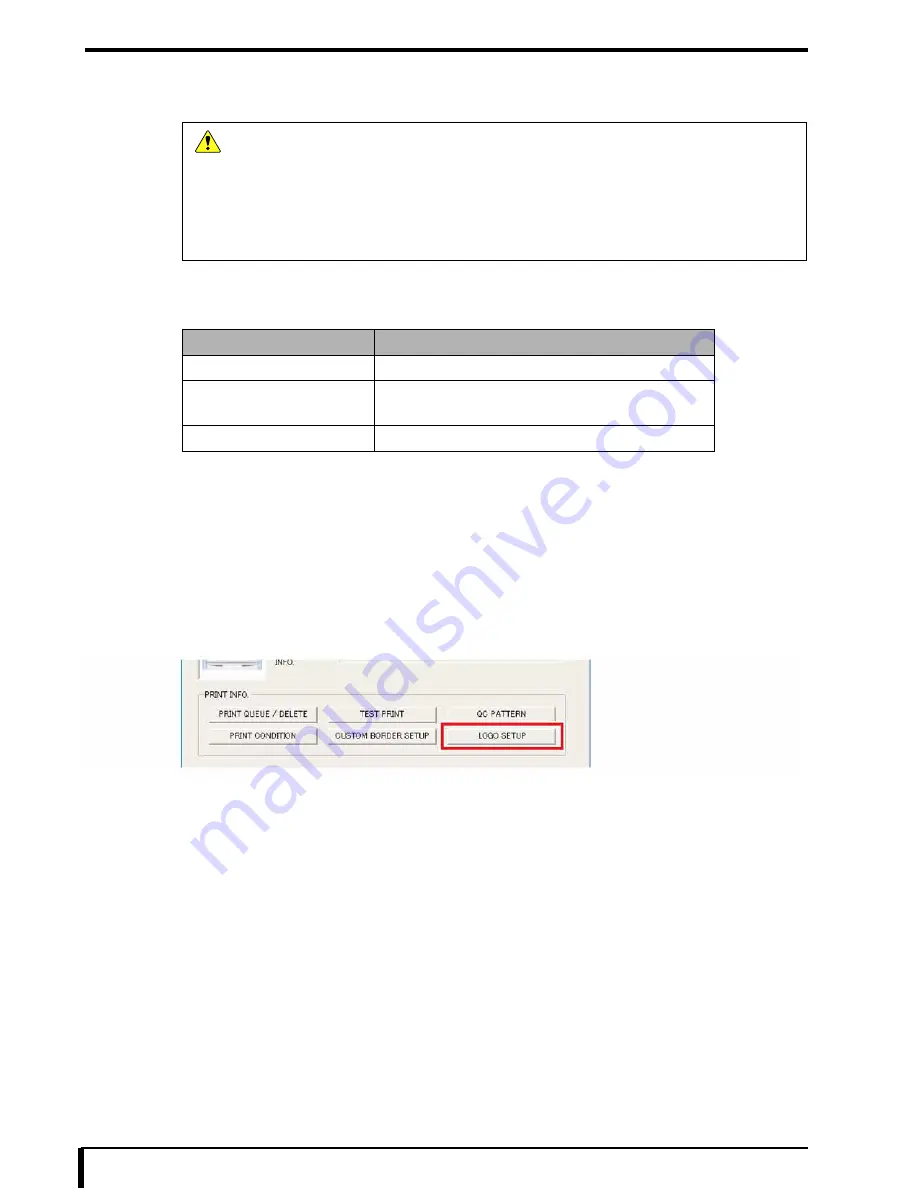

Click the [LOGO SETUP] button under “PRINT INFO”.

The “LOGO SETUP” window appears.

Caution

•

Save the original logo data into the specified folder of the PC, in order to be backed up.

•

The logo mark cannot be set from the maintenance tool.

•

If the stamp area and logo mark output position overlap one another, the stamp area takes

precedence over the logo mark output position.

•

Settings by CH cannot be made, so one setting is made for each system.

•

To use the “OVERLAY” function of Printlink5-IN, use the Printlink5-IN logo settings, and set

the DRYPRO 832 logo data output to “OFF”.

Item

Requirements

File format

bmp format

File size (recommended

value)

•

86

×

86 pixels (maximum 110 pixels)

•

Any aspect ratio may be selected.

Tone

Grayscale 8 bits

Summary of Contents for Drypro 832

Page 2: ......

Page 12: ......

Page 22: ......

Page 28: ......

Page 74: ......

Page 118: ......

Page 228: ......

Page 242: ......

Page 388: ......

Page 498: ......

Page 521: ...18 23 18 5 Block Diagram ...

Page 527: ...18 29 18 7 Printing Operation Load Timing Chart Standard 1 ch ...

Page 529: ......