6

10

13

KEB COMBIVERT F5

Name: Basis

17.02.03

6

Section

Page

Date

©

KEB Antriebstechnik, 2002

All rights reserved

Chapter

Functional Description

Encoder Interface

This parameter exists only at F5-S. The system position of the attached resolver

system is adjusted (factory setting).

With this parameter it is possible to adjust the controller to a not aligned motor. If the

system position of the motor is unknown an automatic trimming can carried out.

Before starting with the adjustment, the direction of rotation must be checked. The

speed display (ru.9) must be positive in the case of clockwise rotation by hand. If that

is not the case, the direction of rotation can be exchanged with Ec.6 as described.

ç enter motor data

ç the connected motor must be able to rotate freely

ç open control release

ç enter Ec.2/12 = 2206

ç close control release

The motor is excited now with its rated current.

If the direction of rotation of the connected motor is not correct or two motor phases

are exchanged, E.EnC is triggered.

For resolver sytems the signal SIN+ and SIN- must be exchanged.

If the system postion displayed in Ec.2/12 no longer changes the alignment is

completed.

ç open control release

If motors with aligned encoder systems are used, the value determined by the

automatic alignment can be entered directly in Ec.2/12.

Absolute position channel 1/

2

(Ec.2 / Ec.12)

(only F5-S)

In order to replace S4-systems by F5-S the following calculation must be carried out:

ec.7 ( S4) * Pole pair number

- Furthermore pay attention to the encoder cable -

- The lower 16 Bit of the result must be entered in Ec.2/12 -

6.10.7 Additional

Parameters

The following parameters are needed only for specific encoder interfaces and are

explained more closely in the appropriate documentation.

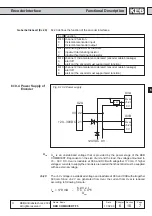

If an SSI-multiturn-absolute value encoder is connected, the number of the bits for

the multiturn-resolution can be adjusted here (12 Bit).

The clock frequency of the SSI-encoder is adjusted in Ec.22. Two clock frequencies

are available 0 : 312,5 kHz or 1 : 156,25 kHz. The smaller clock frequency should

only be adjusted for long cables or in case interferences occur.

The unit supports two data formats for the SSI-encoders:

0 : binary coded

1 : Gray code

As reference speed the max. tachometer speed is adjusted in Ec.25.

Position value directly from encoder channel 1 / 2 (with complete revolutions).

Ec.31 and Ec.32 show the position values of channel 1 and 2 after the gearbox.

SSI Multiturn resolution

(Ec.21)

SSI Clock frequency select

(Ec.22)

SSI Data code (Ec.23)

Nominal tacho speed (Ec.25)

Position channel 1 direct

(Ec.29)

Position channel 2 direct

(Ec.30)

Position Channel 1 (Ec.31)

Position Channel 2 (Ec.32)