10-10

Human-Machine Interface

BE1-951

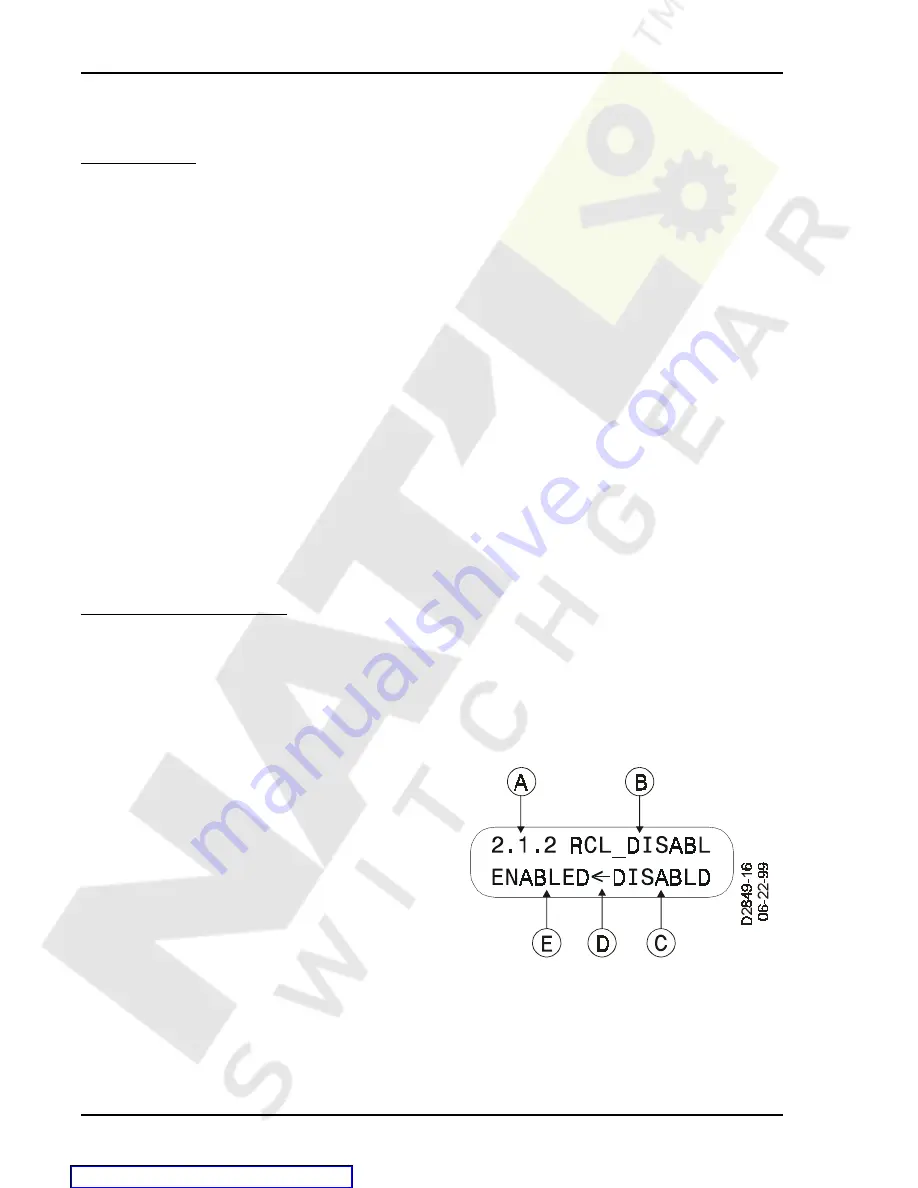

Figure 10-9. Virtual Control Switch 143 Screen

HMI OPERATIONS

The following paragraphs describe how the HMI is used to set and control relay functions.

Entering Settings

Settings for protection functions can be edited at menu branch 5,

PROTECTION LOGIC of the HMI LCD.

Settings for general and reporting functions can be edited from menu branch 6,

GENERAL SETTINGS. To

edit a setting using the manual scrolling pushbuttons, perform the following procedures.

1.

Scroll to the screen that displays the function to be edited.

2.

Press the EDIT pushbutton to gain access. If password security has been initiated for settings, you will

be prompted to enter the appropriate password. See the paragraphs,

Entering Passwords, for details

on entering passwords from the HMI. Once access has been gained, the EDIT LED will be lighted and

a cursor will appear in the first settings field on the screen.

3.

Press the UP or DOWN scrolling key to select the desired setting. Some settings require entering a

number one character at a time. For example, to enter a 51 pickup as 7.3 amps, you would press the

UP pushbutton until the 7 is showing. Then, press the RIGHT pushbutton to move the cursor over and

press the UP pushbutton until the . is showing. Then, press the RIGHT pushbutton to move the cursor

over and press the UP pushbutton until the 3 is showing. Other settings require scrolling through a list

of selections. For example, you would move the cursor over to the CRV field and then scroll through

a list of available TCC curves.

4.

Once all of the settings on the screen have been entered, press the EDIT pushbutton a second time and

the settings will be validated. If the settings are in range, the screen will flash CHANGES SAVED, and

the EDIT LED will go out. If you want to abort the edit session without changing any settings, press the

RESET pushbutton before you press the edit pushbutton the second time. The screen will flash

CHANGES LOST and the EDIT LED will go out.

Performing Control Operations

Control operations can be executed at menu branch 2,

CONTROL of the HMI LCD. These functions allow

you to control the state of virtual switches, override logic and control the active setting group, and override

the logic and control the state of output contacts. All of these functions work similarly to the process of

entering settings in that you press the EDIT pushbutton, use the UP and DOWN scroll pushbuttons to select

the desired state, and press the EDIT pushbutton for the action to be executed.

Figure 4-3 shows virtual switch 143 as an example of a

virtual switch screen. See Section 4,

Protection And

Control for more details on the x43 and 101 functions.

Table 10-2 describes each of the call-outs shown on

figure 10-9. The user programmable label for this switch

has been set to RCL_DISABL. The TRUE (closed)

state label has been set to DISABLD. And, the FALSE

(open) state label has been set to ENABLED. The

logical mode for this application would be set to Mode

2 (On/Off switch).