Error

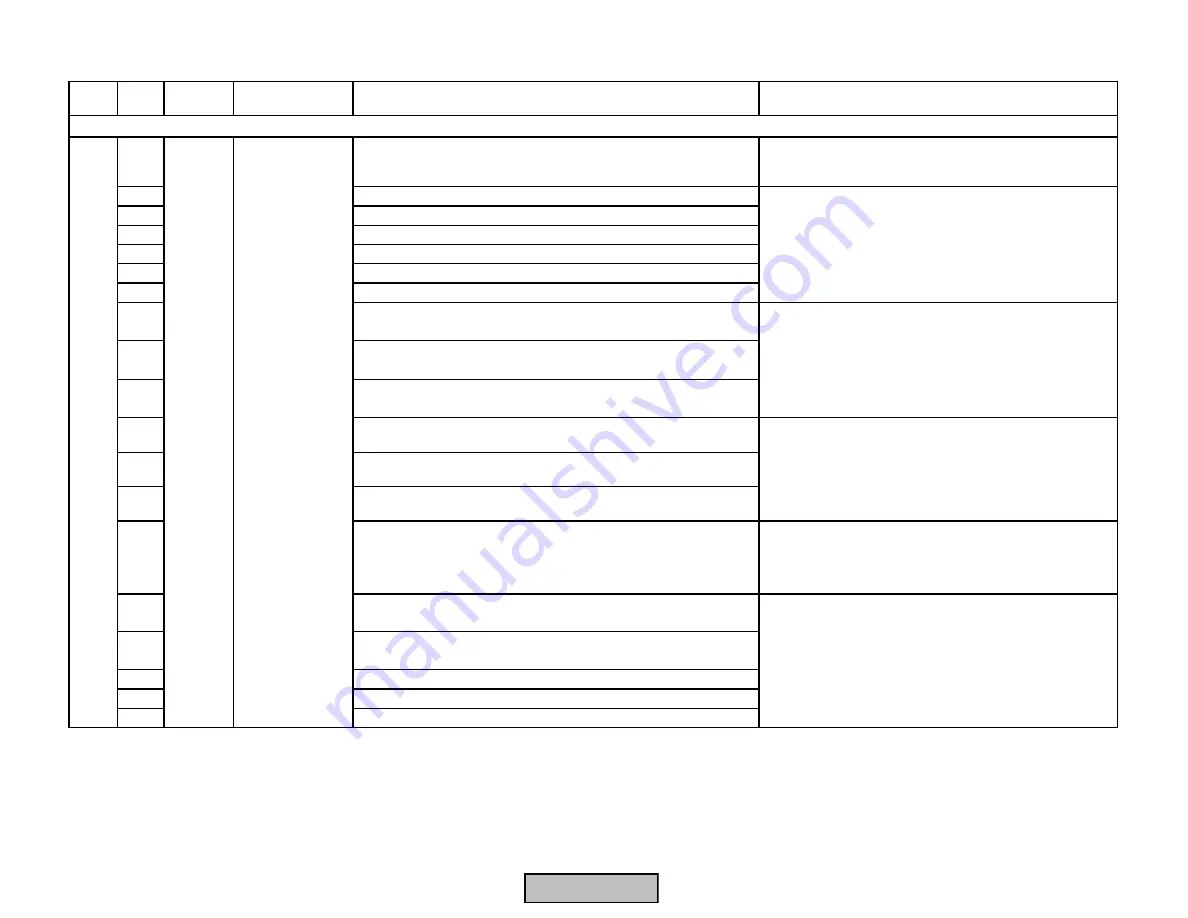

Code

Diag.

Code

Device

Display

Meaning for the LMV5x System

Corrective Action

Any #

Basic unit has detected a plausibility fault in the ratio control

system.

The diagnostic code describes the cause of the fault

(see below).

00

Ratio curve of the air actuator is not fully defined

01

Ratio curve of the fuel actuator is not fully defined

02

Ratio curve of auxiliary actuator 1 is not fully defined

03

Ratio curve of auxiliary actuator 2 is not fully defined

04

Ratio curve of auxiliary actuator 3 is not fully defined

05

VSD curve is not fully defined

0A

Calculated P-part outside the permissible range

0B

Calculated I-part outside the permissible range

0C

Calculated system delay time outside the permissible range

0D

Calculated O2 setpoint outside the permissible range

0E

Calculated O2 min. value outside the permissible range

0F

Calculated O2 ratio value outside the permissible range

14

Calculated standardized value lies outside the permissible

range

Check if the correct values have been entered for the

standardized values.

Readjust O2 trim control, if required, or repeat the

settings.

20

With hysteresis compensation: Permissible target positioning

range exceeded

21

The load / point number predefined by the AZLI lies outside

the permissible range

22

Unplausible program branch

23

Unplausible fuel-air ratio phase

40

Unplausible target positions

16

LMV5

If fault occurs sporadically, reduce electrical noise.

If fault occurs continuously, replace LMV5.

Internal Fault

Basic Unit

Check parameters (P Low-Fire, I Low-Fire, Tau Low

Fire, P High-Fire, I High-Fire, Tau High-Fire). These

values normally self-set when the delay time is

measured. Check the values of these parameters

against the maximum and minimum ranges. Readjust

O2 control curve if necessary.

The O2 control curve must be 0.1% O2 lower than the

%O2 measured at the ratio control curve, and 0.1%

above the O2 alarm curve. Readjust curves.

Ensure that actuators that are addressed and activated

have their positions defined. Check curve points to see

if correct values have been entered for the actuator or

VSD. Readjust the ratio curve, if required.

Fault with Base Unit (LMV5) Ratio Control, O2 Trim, VSD

Section 7

Page 26

SCC Inc.

HOME

HOME

Summary of Contents for LMV 5 Series

Page 2: ...Intentionally Left Blank ...

Page 41: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 7 Section 2 HOME ...

Page 42: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 8 SCC Inc HOME ...

Page 43: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 9 Section 2 HOME ...

Page 44: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 10 SCC Inc HOME ...

Page 45: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 11 Section 2 HOME ...

Page 46: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 12 SCC Inc HOME ...

Page 47: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 13 Section 2 HOME ...

Page 48: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 14 SCC Inc HOME ...

Page 49: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 15 Section 2 HOME ...

Page 50: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 16 SCC Inc HOME ...

Page 51: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 17 Section 2 HOME ...

Page 52: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 18 SCC Inc HOME ...

Page 53: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 19 Section 2 HOME ...

Page 54: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 20 SCC Inc HOME ...

Page 55: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 21 Section 2 HOME ...

Page 373: ...Intentionally Left Blank ...