Technical

Instructions

LMV

Series

Document

No.

LV5

‐

1000

Section

6

Page

34

SCC

Inc.

If

a

combustion

air

temperature

sensor

is

installed

and

activated,

the

air

temperature

will

be

recorded

when

the

last

point

is

entered

into

the

O

2

Control

Curve.

This

temperature

is

stored

under

the

following

menu

path:

Params

&

Display

>

O2Contr/Alarm

>

Gas/Oil

Settings

>

Startmode

>

Adjust.

Temp

O2

This

is

the

temperature

that

will

be

compared

against

the

current

air

temperature

to

perform

temperature

compensated

light

‐

off

if

parameter

StartMode

is

set

to

“IgnLoadTC”

or

“IgnPtWithTC”

(LMV52.440

only).

When

terminal

X5

‐

03.2

is

properly

configured

(see

Section

3

‐

Parameters),

it

can

be

energized

to

cause

a

deactivation

of

the

O

2

trim.

When

this

is

done,

the

LMV52

will

operate

on

the

O

2

Ratio

Control

Curve.

The

O

2

rich

and

lean

limits

will

be

active

as

long

as

there

is

a

valid

O

2

signal.

This

deactivation

via

X5

‐

03.2

occurs

without

a

notification

being

displayed

on

the

AZL52.

Pre

‐

purge

must

be

set

so

that

20.9%

(+/

‐

2.0%

O

2

)

is

read

by

the

QGO20

sensor.

If

this

is

not

met,

a

lockout

or

deactivation

will

occur

depending

on

the

setting

of

parameter

OptgMode

.

When

using

the

LMV52.440

on

low

or

ultra

‐

low

NOx

mesh

burners,

a

StartMode

of

“IgnPtWithTC”

is

typically

used

combined

with

adjusting

O2InitOffset

in

the

negative

direction

(more

rich).

If

done

properly,

this

should

make

the

transition

from

light

‐

off

position

to

low

fire

richer

than

normal

operation

so

that

the

transition

is

stable

and

reliable

under

varying

environmental

conditions.

While

the

burner

is

being

held

at

Point

2

awaiting

NumberTauSuspend

to

expire,

the

O2InitOffset

will

gradually

dissolve

and

the

%O

2

will

be

trimmed

to

setpoint

before

the

burner

is

released

to

modulate.

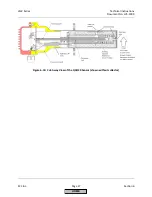

The

AGO

gas

collector

should

be

mounted

per

the

requirements

shown

below:

HOME

Summary of Contents for LMV 5 Series

Page 2: ...Intentionally Left Blank ...

Page 41: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 7 Section 2 HOME ...

Page 42: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 8 SCC Inc HOME ...

Page 43: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 9 Section 2 HOME ...

Page 44: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 10 SCC Inc HOME ...

Page 45: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 11 Section 2 HOME ...

Page 46: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 12 SCC Inc HOME ...

Page 47: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 13 Section 2 HOME ...

Page 48: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 14 SCC Inc HOME ...

Page 49: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 15 Section 2 HOME ...

Page 50: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 16 SCC Inc HOME ...

Page 51: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 17 Section 2 HOME ...

Page 52: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 18 SCC Inc HOME ...

Page 53: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 19 Section 2 HOME ...

Page 54: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 20 SCC Inc HOME ...

Page 55: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 21 Section 2 HOME ...

Page 373: ...Intentionally Left Blank ...