6.8. Product calibration

The seeding tables that contain the basic values for adjusting the seeding quantity are located

under the transmission cover in the seed drill. The seeding tables are provided in section 6.5.

Seeding quantities. However, there are great differences between various seeds, which is why

the actual seeding quantity must always be checked with a calibration test. Seed treatment, such

as seed dressing, has considerable impact on uidity.

The calibration test should be performed whenever changes are made to the feeding quantities.

In particular, fertiliser quantities may vary a lot due to the moisture and uidity of the fertiliser

When driving on the road with hoppers full of fertiliser and seeds, the vibration may cause

arching in the hoppers. In the autumn or after rain, the fertiliser may absorb humidity in the

feeders, changing fertiliser uidity. For this reason, it is good to monitor that fertiliser or seed

ow evenly from all feeders when seeding begins. Performing a calibration test is in order and

visually checking that the feed quantity is even is all feeders.

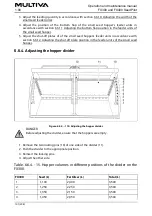

Figure. 6.8. - 134. Pulley

When performing a calibration test, the machine must be raised from its working

position so that the pulley (1) comes off of the tyres.

6.8.1. Fertiliser calibration test on a machine without a gearbox or

with a gearbox on the seed side

DANGER

If the machine is equipped with a SeedPilot or SeedPilot ISOBUS control system, turn on

the STOP ALL function in accordance with section 6.3.1. Using the STOP ALL function.

Operation and maintenance manual

1.00

FX300 and FX400 SeedPilot

111 (208)

Summary of Contents for FX300 SeedPilot

Page 200: ...Hydraulic schematics FX300 and FX400 1 Hydraulic schematics FX300...

Page 201: ...Hydraulic schematics FX300 and FX400 2...

Page 202: ...Hydraulic schematics FX300 and FX400 3 Hydraulic schematics FX400...

Page 203: ...Hydraulic schematics FX300 and FX400 4...

Page 204: ...Electrical schematics FX300 and FX400 1 Electrical schematics...