9.

Ensure that the tractor’s parking brake is engaged and the middle marker ball valve

is in the closed position before performing the calibration test.

Ensure that the markers have settled in the transport position and their ball valves

have been closed before moving.

1

pc

10.

Read the operation and maintenance manual carefully before operation

1

pc

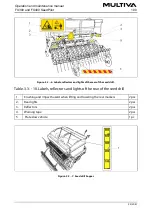

Figure. 3.3. - 3. Right side labels of the seed drill

Table. 3.3. - 7. Right side labels of the seed drill

1.

Falling hazard, do not climb on top of the wheel

2 pcs, at both ends of the

working platform

2.

Falling hazard

2 pcs, at both ends of the

working platform

3.

Crushing and impact hazard when lifting and

lowering the middle markers

2 pcs, on both middle markers

4.

Adjustment direction, increases clockwise

1 pc

5.

Adjustment direction, increases counterclockwise

1 pc

6.

Cutting hazard

2 pcs, on both sides of the

machine

7.

Crushing hazard

2 pcs, on both sides of the

machine

Operation and maintenance manual

1.00

FX300 and FX400 SeedPilot

19 (208)

Summary of Contents for FX300 SeedPilot

Page 200: ...Hydraulic schematics FX300 and FX400 1 Hydraulic schematics FX300...

Page 201: ...Hydraulic schematics FX300 and FX400 2...

Page 202: ...Hydraulic schematics FX300 and FX400 3 Hydraulic schematics FX400...

Page 203: ...Hydraulic schematics FX300 and FX400 4...

Page 204: ...Electrical schematics FX300 and FX400 1 Electrical schematics...