3. SIGNALS AND WIRING

3 - 13

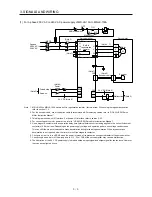

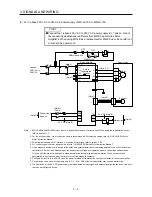

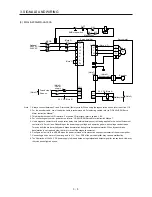

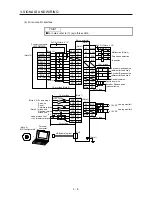

3.2.3 Torque control mode

POINT

EM2 has the same function as EM1 in the torque control mode.

(1) For sink I/O interface

Servo amplifier

(Note 6)

CN1

(Note 1)

9

(Note 2)

47

DOCOM

46

DOCOM

48

ALM

23

ZSP

4

LA

5

LAR

6

LB

7

LBR

34

LG

33

OP

SD

10 m or less

2 m or less

(Note 6)

CN1

49

RD

8

LZ

LZR

(Note 6)

CN1

20

DICOM

21

DICOM

+

CN3

27

2 m or less

28

2

TC

SD

VLA

LG

Analog torque command

±8 V/maximum torque

(Note 8) Analog speed limit

0 to ±10 V/rated speed

(Note 7)

MR Configurator2

42

15

19

41

EM2

SON

RS1

RS2

RA1

RA2

RA3

2 m or less

26

MO1

30

LG

29

MO2

± 10 V DC

± 10 V DC

SD

24 V DC (Note 4)

10 m or less

24 V DC (Note 4)

-8 V to +8 V

-10 V to +10 V

Forward rotation start

Reverse rotation start

Forced stop 2

Servo-on

(Note 3)

(Note 9)

Power supply

Plate

Plate

Plate

Ready

Malfunction (Note 6)

Zero speed detection

Encoder A-phase pulse

(differential line driver)

Encoder Z-phase pulse

(differential line driver)

Encoder B-phase pulse

(differential line driver)

Control common

Encoder Z-phase pulse

(open collector)

Analog monitor 1

Analog monitor 2

USB cable (option)

Personal

computer

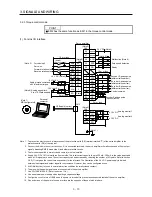

Note 1. To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo amplifier to the

protective earth (PE) of the cabinet.

2. Connect the diode in the correct direction. If it is connected reversely, the servo amplifier will malfunction and will not output

signals, disabling EM2 (Forced stop 2) and other protective circuits.

3. The forced stop switch (normally closed contact) must be installed.

4. Supply 24 V DC ± 10% to interfaces from outside. The total current capacity is up to 300 mA. 300 mA is the value applicable

when all I/O signals are used. The current capacity can be decreased by reducing the number of I/O points. Refer to section

3.9.2 (1) that gives the current value necessary for the interface. The illustration of the 24 V DC power supply is divided

between input signal and output signal for convenience. However, they can be configured by one.

5. ALM (Malfunction) turns on in normal alarm-free condition (normally closed contact).

6. The pins with the same signal name are connected in the servo amplifier.

7. Use SW1DNC-MRC2-E. (Refer to section 11.4.)

8. Use an external power supply when inputting a negative voltage.

9. Configure a circuit to turn off EM2 when the power is turned off to prevent an unexpected restart of the servo amplifier.

10. Plus and minus of the power of source interface are the opposite of those of sink interface.

Summary of Contents for MELSERVO-JE MR-JE-100A

Page 23: ...1 FUNCTIONS AND CONFIGURATION 1 12 MEMO ...

Page 29: ...2 INSTALLATION 2 6 MEMO ...

Page 91: ...3 SIGNALS AND WIRING 3 62 MEMO ...

Page 171: ...5 PARAMETERS 5 44 MEMO ...

Page 195: ...6 NORMAL GAIN ADJUSTMENT 6 24 MEMO ...

Page 221: ...7 SPECIAL ADJUSTMENT FUNCTIONS 7 26 MEMO ...

Page 249: ...8 TROUBLESHOOTING 8 28 MEMO ...

Page 255: ...9 DIMENSIONS 9 6 MEMO ...

Page 263: ...10 CHARACTERISTICS 10 8 MEMO ...

Page 293: ...11 OPTIONS AND PERIPHERAL EQUIPMENT 11 30 MEMO ...