Chapter 8 Communications

ASDA-B2

8-10

Revision May, 2018

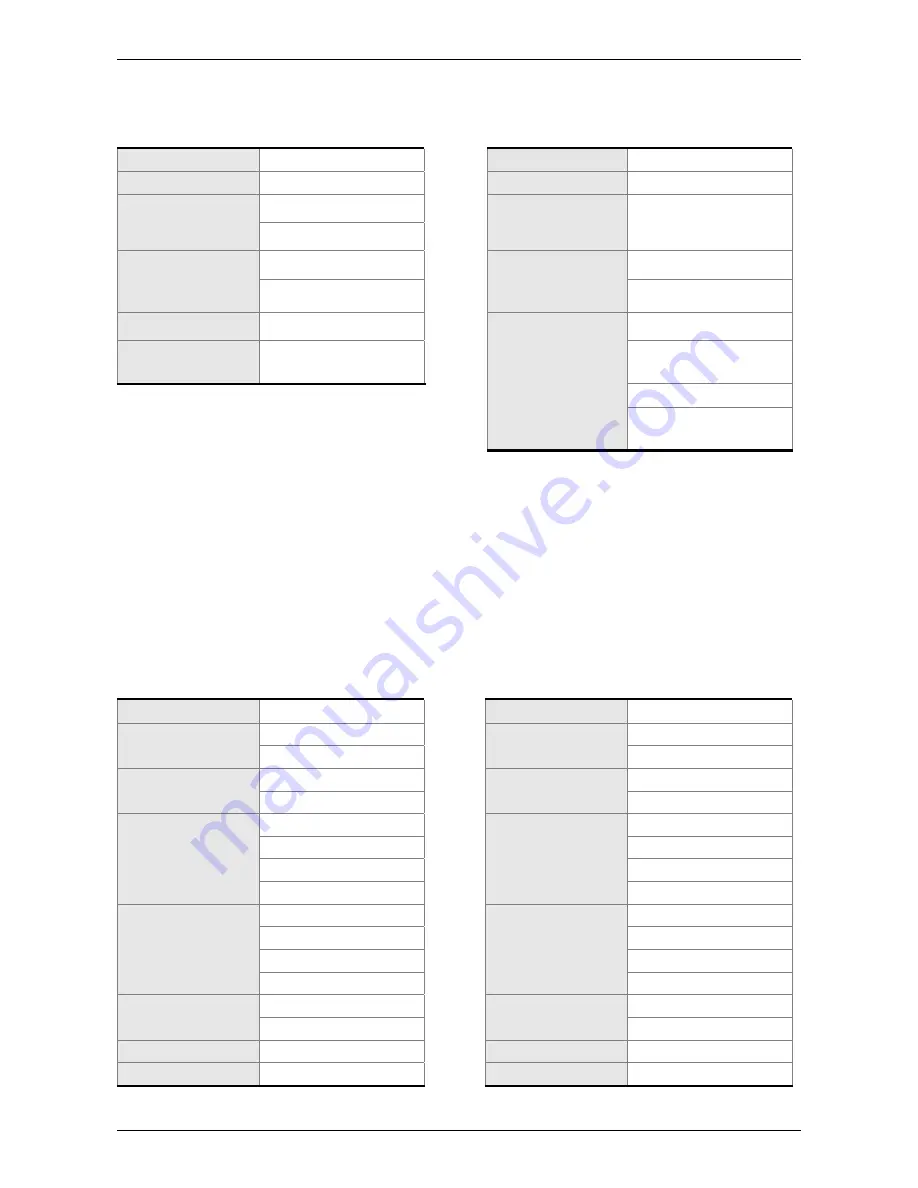

RTU Mode:

Command message (Master):

Response message (Slave):

Slave address

01H

Slave address

01H

Function 03H

Function 03H

Starting data

address

02H (High)

Number of data

(In Byte)

04H

00H (Low)

Number of data

(In Word)

00H

Contents of

starting data

address 0200H

00H (High)

02H

B1H (Low)

CRC Check Low

C5H (Low)

Contents of

second data

address 0201H

1FH (High)

CRC Check

High

B3H (High)

40H (Low)

CRC Check Low A3H (Lower bytes)

CRC Check

High

D4H (Upper bytes)

Note: Before and after the transmission in RTU mode, 10 ms of silent interval is needed.

Example 2: function code 06H, write single word:

The Master issues command to the 1

st

Slave and writes data 0064H to address 0200H.

The Slave sends the response message to the Master after the writing is completed.

The calculation of LRC and CRC will be described in next chapter.

ASCII Mode:

Command message (Master):

Response message (Slave)

:

Start ‘:’

Start ‘:’

Slave address

‘0’

Slave address

‘0’

‘1’

‘1’

Function

‘0’

Function

‘0’

‘6’

‘6’

Starting data

address

‘0’

Starting data

address

‘0’

‘2’

‘2'

‘0’

‘0’

‘0’

‘0’

Content of data

‘0’

Content of data

‘0’

‘0’

‘0’

‘6’

‘6’

‘4’

‘4’

LRC Check

‘9’

LRC Check

‘9’

‘3’

‘3’

End 1

(0DH)(CR)

End 1

(0DH)(CR)

End 0

(0AH)(LF)

End 0

(0AH)(LF)