HOW TO USE THIS MANUAL

1

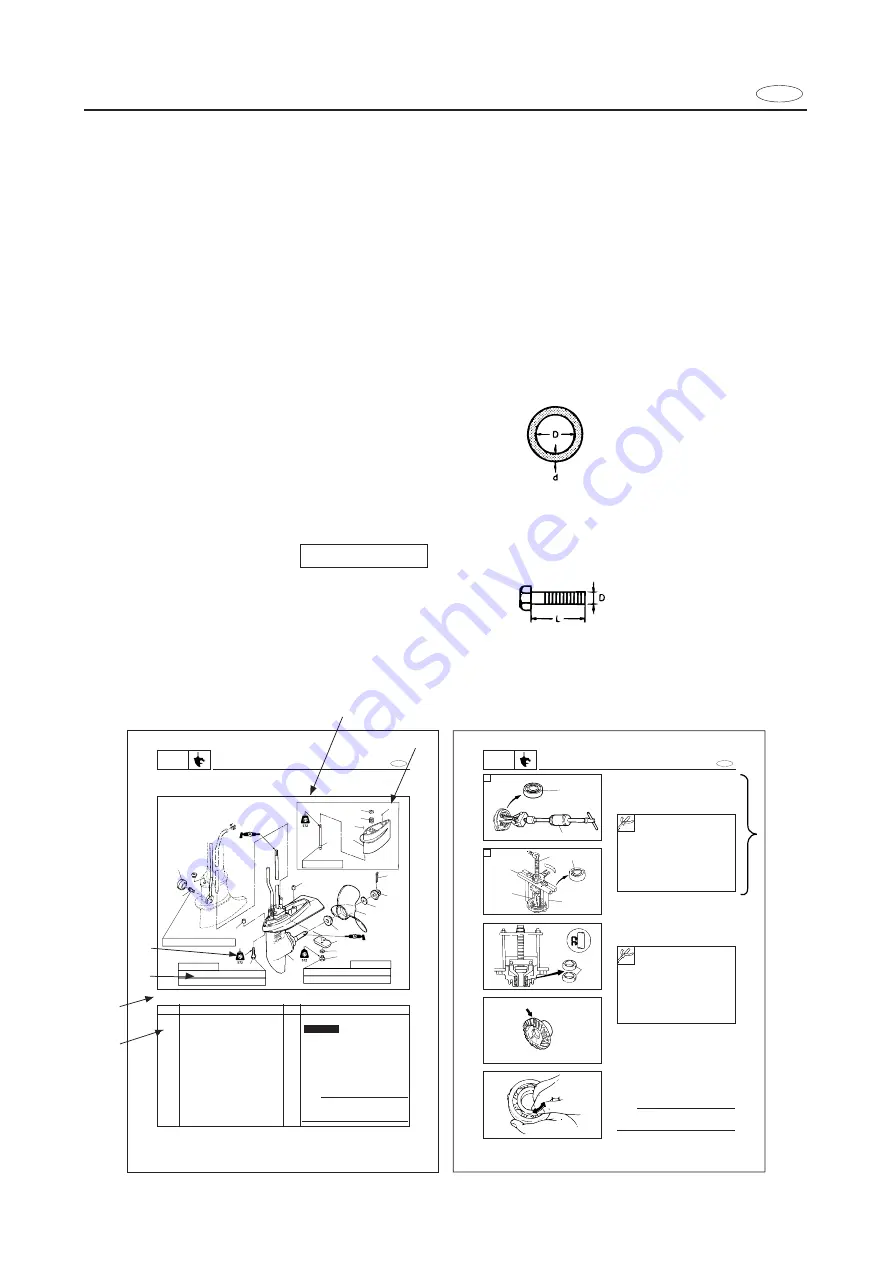

To help identify parts and clarify procedure steps, there are exploded diagrams at the

start of each removal and disassembly section.

2

Numbers are given in the order of the jobs in the exploded diagram. A circled number

indicates a disassembly step.

3

Symbols indicate parts to be lubricated or replaced (see “SYMBOLS”).

4

A job instruction chart accompanies the exploded diagram, providing the order of jobs,

names of parts, notes in jobs, etc.

Example:

O-ring size

39.5 x 2.5 mm: Inside diameter (D) x ring diameter (d)

5

Dimension figures and the number of parts, are provided for fasteners that require a

tightening torque:

Example:

Bolt or screw size

10 x 25 mm (2) : M10(D) x 25 mm (L) (2pieces)

6

Jobs requiring more information (such as special tools and technical data) are described

sequentially.

E

E

LOWER UNIT

LOWR

LOWER UNIT

EXPLODED DIAGRAM

z

For long

9

10

14

11

12

5

4

3

2

1

8

7

6

10 Nm (1.0 m•kg, 7.2 ft•lb)

11

13

17

16

15

M6 x 40 mm

M6 x 167 mm

15

M6 x 16 mm

14

1st 3 Nm (0.3 m•kg, 2.17 ft•lb)

2nd 8 Nm (0.8 m•kg, 5.8 ft•lb)

1st 3 Nm (0.3 m•kg, 2.17 ft•lb)

2nd 8 Nm (0.8 m•kg, 5.8 ft•lb)

6-1

REMOVAL AND INSTALLATION CHART

Step

1

2

3

4

5

6

7

8

9

10

Q’ty

1

1

1

1

1

1

1

1

1

1

Service points

Follow the left “Step” for removal.

NOTE

Set the shift lever to reverse position

and loosen the bolt (shift rod connec-

tor).

Not reusable

Procedure/Part name

LOWER UNIT REMOVAL

Cotter pin

Propeller nut

Washer

Propeller

Spacer

Bolt (anode)

Toothed washer (anode)

Anode

Grommet

Bolt (shift rod connector)

Lower casing cap oil seal removal

1. Remove:

9

Oil seals

1

Lower casing cap/Propeller shaft bearing

removal

1. Remove:

9

Ball bearing

1

A

For USA and CANADA

B

Except for USA and CANADA

E

LOWER CASING CAP ASS’Y

LOWR

1

2

3

4

1

6

5

1

6-12

Slide hammer set

2

:

YB-06096

Stopper guide plate

3

:

90890-06501

Bearing puller

4

:

90890-06535

Bearing puller craw

5

:

90890-06537

Stopper guide stand

6

:

90890-06538

Slide hammer set:

YB-06096

Stopper guide plate:

90890-06501

Bearing puller:

90890-06535

Bearing puller craw:

90890-06537

Stopper guide stand:

90890-06538

SERVICE POINTS

Gears inspection

1. Inspect:

9

Tooth

9

Dog

Wear/Damage

®

Replace.

Bearings inspection

1. Inspect:

9

Bearing

Pitting/Rumbling

®

Replace.

NOTE:

Turn the bearing by fingers and check the

bearing pitching

A

B

3

4

5

6

2

1

2

9

9

9

9

9

Содержание F4

Страница 106: ...E FUEL PUMP FUEL 4 7 SERVICE POINTS Fuel pump inspection 1 Inspect 9Diaphragm Damage Replace ...

Страница 296: ...E TRBL ANLS CHAPTER 9 TROUBLE ANALYSIS TROUBLE ANALYSIS 9 1 TROUBLE ANALYSIS CHART 9 1 ...

Страница 306: ......

Страница 307: ...Printed in JAPAN February 1998 2 09 1 n 67D 28197 Z8 C1 F4AMH Printed on recycled paper YAMAHA MOTOR CO LTD ...