SD20-G Series

333

speed.

Motor shaft vibrates

side to side.

Rotation inertia ratio

of load (Po013) is

too high.

If servo drive runs safely, please

recognize inertia again according to

chapter 7.3.

Adjust gain according chapter 7.

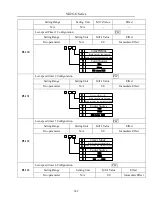

9.1.3 Torque control mode

Start-up process

Description

Cause

Countermeasures

Connect control

powe(L1C,L2C)

and main power

supply(R/L1 ,S/L

2, T/L3)

Digital tube is not on

or green light is not

on

1. Control

terminal is

disconnected

Rewire

Connect L1C/L2C power cable to

socket separately.

2.Control power

supply fault

Check the voltage between L1C and

L2C

Note: 380V servo drive doesn’t need

to connect to L1C and L2C.

3.Servo drive fault

Please contact with manufacturer.

Keypad panel

displays ’AL-XXX’.

Refer to chapter 9.2 to find the cause and solve the problem.

Servo drive

enabled signal is

valid

(

/S-ON is

ON

)

Kaypad panel

displays ’AL-XXX’.

Refer to chapter 9.2 to find the cause and solve the problem.

Servo motor is in

unlocked state.

1. Servo drive

enabled signal is

invalid

Check whether green light is on, if it is

not, take the following step.

Check whether Po004=0, if it is not,

set 0 to Po004, then repower on.

Check whether Lo-15.A is 1, if it is

not, check whether wiring is correct.

2.Control mode is

wrong

Check whether Po001.X is correct.

Input torque

command

Servo motor doesn’t

rotates or speed is

not correct.

1. Lo-13 has no

change.

2. Forward and

reverse running is

prohibited.

Analog interface wiring is wrong.

Check whether analog wiring is correct

when set command source by Po428,

referring to chapter 4.

No speed command is input.

1. Check whether DI function 2 (forward

torque limit) or DI function 3(reverse torque

limit) is used.

2. Check whether DI function 11 (common

pulse prohibited) is used.

3. Check whether Po429 is set correctly.

4.Check whether Po204 is zero when digital

command is given.

Servo motor is

galloping.

Encoder cable fault

1. Check whether Lo-04 value is correct

when motor rotates 1 revolution.

2. Check whether servo drive trips into

AL-17

U/V/W motor cable is wrong

Содержание SD20-G Series

Страница 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Страница 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Страница 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Страница 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Страница 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

Страница 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...