SD20-G Series

220

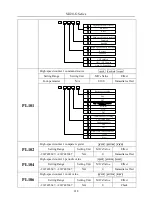

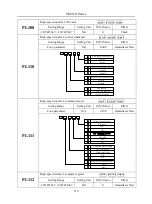

PL114

High-speed counter 2 periodic value

speed position torque

Setting Range

Setting Unit

Mfr’s Value

Effect

-21472147483647

N/A

0

Immediate effect

PL116

High-speed counter 2 count value

speed position torque

Setting Range

Setting Unit

Mfr’s Value

Effect

-21472147483647

N/A

0

Check

PL118

High-speed counter2 CAP value

speed position torque

Setting Range

Setting Unit

Mfr’s Value

Effect

-21472147483647

N/A

0

Check

When using the function of high-speed counter, set the pulse source according to PL101.C and PL111.C,

servo drive starts to use different high-speed counter based on the setting of PL101.C and PL111.C. In the

condition of correct external connection, the pulse received by servo drive will be displayed on the count

value of the corresponding high-speed counter.

If using CAP function, servo drive stores the counter value into CAP value in the rising edge of CAP

command, the source of CAP are software, DI7 and DI8, meanwhile user can set the periodic value

(PL104&PL114) as required, servo drive latches pulses in the rising edge of CAP or setting period. When

using the function of CAP period, since CAP happens in random time of pulse, servo drive will compare

actual reveiced pulse with the pulse captured from edge, then makes compensation to make the pulse

count value equal to CAP value finally.

When using RESET function, servo drive will clear out the count value.

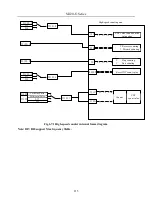

6.8 Built-in PLC Function

6.8.1 Summary

Servo built-in PLC function is a specific function of SD20 servo system, user can controlservo drive

bysimple command, it is convenient for the use of special occasion.

SD20 built-in PLC can operate internal 8 DIs, 5 DOs, 2 groups of pulse receive, 1 groupofpulseoutput, 2

analog inputs and 1 analog output. The program written by user is running in the servo software

back-ground, every main cycl period runs 5 instructions continuously, in general, it runs 4000 commands

for average 100ms, software can provide 4 low-speed timers, 2 high-speed counters and 2 high-speed

timers.

When setting Po001 as d x 22, servo drive enters built-in PLC special control mode, the commands of

position,speed and torque need to set by built-in PLC, the other singals such as enabled signal still set by

terminal or parameter. When setting Po001 to other control mode, PLC is still running, meanwhile

operating mode still runs according to the setting value of Po001.

Содержание SD20-G Series

Страница 35: ...SD20 G Series 35 M3 structure Fig 3 1 5 Servo drive structure 3...

Страница 36: ...SD20 G Series 36 ML3 structure 118 5 5 7 5 93 297 8 223 118 93 0 5 12 5 7 5 4 M4...

Страница 38: ...SD20 G Series 38 M4 structure Approx mass 10 365 kg Fig 3 1 7 Servo drive structure 5...

Страница 39: ...SD20 G Series 39 M5 structure Approx msaa 11 1Kg Fig 3 1 8 Servo drive structure 6...

Страница 40: ...SD20 G Series 40 M6 structure Approx mass 17 4Kg Fig 3 1 9 Servo drive structure 7...

Страница 182: ...SD20 G Series 182 Fig 6 4 44SD20E Cam internal frameworkdiagram...