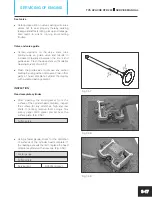

Fig. 3.2

Fig. 3.3

l

If the compression pressure is low, pour 3 to

5 cc of clean engine oil into the cylinder

through the sparkplug hole and re-check the

compression pressure. If the compression

pressure increases from the previous value,

then check the following.

-

Leaking cylinder head gasket.

-

Worn piston rings.

-

Worn cylinder and piston.

-

Piston ring stuck in the grooves.

l

If the compression pressure is the same as the

previous value, check the valves for leakage

and carburettor piston valve opening.

CLUTCH - SERVICING

REMOVAL

Clutch assembly can be serviced with the engine

mounted on the vehicle itself. Normally clutch is

serviced for:

- Loss of power / low pickup

- Jerking of vehicle

- Any abnormal noise from clutch

- Kick slip

l

Drain engine cum transmission oil as explained

in chapter “Periodic maintenance” page no.

2-12.

l

After draining always measure the oil quantity

using a measuring jar.

l

Remove filter complete engine oil as explained

in chapter “Periodic maintenance” page no.

2

.

-13

l

Loosen lock nut (A) and adjusting nut (B) from

the cable assembly clutch mounting. (Fig. 3.2)

12 mm spanner

l

Using 20 mm open end spanner rotate the arm

clutch release towards front, in such a way that

cable assembly clutch can be dislocated from

the arm clutch release. (Fig. 3.3)

20 mm spanner

TVS APACHE RTR 200

SERVICE MANUAL

SERVICING OF ENGINE

A

B

3-2