Piston

l

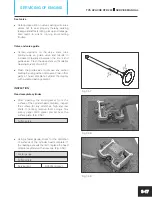

Remove the ring piston top (1st) (A), piston ring

2nd (B) and oil rings (C) along with separator oil

ring (D). (Fig. 3.88)

Caution:

Do not expand the rings more, it may lose

it‘s mechanical properties.

l

Decarbonise the piston and piston ring

grooves. After cleaning the grooves, fit the

rings and rotate them in their respective

grooves to make sure that they rotate freely.

(Fig. 3.89)

l

Carbon in the grooves is liable to cause the

rings piston to stuck in the grooves, and this

will lead to reduced engine power output.

Note:

While cleaning the ring grooves of the

piston, take care not to damage the

grooves. Use an old broken ring to clean

the grooves.

l

If a piston sliding surface is badly scored or

scuffed due to overheating, it must be

replaced. Shallow grooves or minor scuff can

be removed by smoothening with a fine emery

paper (400 grade). (Fig. 3.90) Inspect the piston

for damage or crack. Replace if required.

l

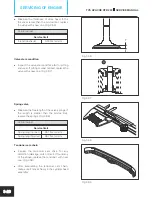

Measure the diameter at the right angle to the

pin piston and at a point which is 10 mm from

the bottom to check wear. If the diameter is

lower than the service limit, replace the piston.

(Fig. 3.91)

Outside micrometer

Size

Grade

Standard

Service Limit

(in mm)

(in mm)

–

A

65.960 ~ 65.965

–

B

65.965 ~ 65.970

65.00

–

C

65.970 ~ 65.975

1st OS

PINK 66.215 ~ 66.220

–

2nd OS

WHITE 66.465 ~ 66.470

–

l

Cylinder to piston clearance is the difference

between piston diameter and bore diameter.

3-27

TVS APACHE RTR 200

SERVICE MANUAL

SERVICING OF ENGINE

Fig. 3.88

A

D

B

C

Fig. 3.89

Fig. 3.90

Fig. 3.91

10 mm