5238-E P-76

SECTION 6 OFFSET FUNCTION

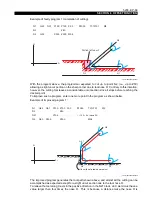

When the radius of the programmed arc equals twice the tool nose R, the cutting tool is

located at the point where the tool nose R comes into contact with both the extension of arc

N2 - N3 and the extension of straight line N3 - N4, after the execution of the commands in

N3 block (see the figure in "1)" above). That is, the cutting tool is positioned right above

point N2, as shown in the figure directly above.

c.

Case where the arc radius is less than "2 x nose R" (impossible):

LE33013R0300800100019

The commands in block N3 specify positioning of the cutting tool at the point where the tool

nose R comes into contact with both the extension of arc N2-N3 and the extension of

straight line N3-N4; however, such a point cannot be obtained. Therefore, when the control

executes the commands in block N3, an alarm occurs and the machine stops.

In this kind of case, cutting using the tool nose radius compensation function is not

possible.

[Supplement]

When cutting inside an arc, the programming must satisfy the following condition:

R 2 x R

N

(where R: arc radius, R

N

: nose R)

N2

N3

N4

Z100

F0.2

I1

Z40

N1

G42

G02

G01

G01

X100

X102

Z80

Z79

S1000

T010101

M04

X

+

Z

+

N4

N3

N2

N1