5238-E P-319

SECTION 13 SCHEDULE PROGRAMS

5.

Schedule Program End Block

[Function]

At the end of a schedule program, an "END" block must always be specified. All blocks specified

following the "END" block are invalid.

[Programming format]

END

6.

Program Example

The procedure to create a schedule program is explained below.

Assume that the NC lathe is equipped with a bar feeder and three different workpieces are

machined according to the programmed schedule.

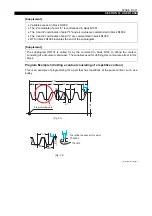

[Program sequence]

Procedure :

1

Determine the file name and the program name (number) of the program to be used for

machining three kinds of parts.

2

Create the program for each part based on the part drawing.

3

To machine these three kinds of parts, determine the order and the number of parts to be

machined.

4

Make the schedule program next. Determine the file name of the schedule program.

Part A

A.MIN, O100

Part B

B.MIN, O200

Part C

C.MIN, O300

Part A

20 pcs.

Part B

15 pcs.

Part C

25 pcs.

File

name

SHAFT-1.SDF