5238-E P-56

SECTION 6 OFFSET FUNCTION

SECTION 6 OFFSET FUNCTION

1.

Tool Nose Radius Compensation Function (G40, G41,

G42)

1-1.

General Description

The tool tip point radius of most cutting tools used in turning operation is the cause of

inconsistencies between the designated tool paths and the actually finished workpiece contour.

With the tool radius compensation function, such geometric error is automatically compensated for

by simple programming.

1-2.

Tool Nose Radius Compensation for Turning Operations

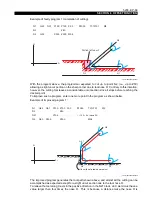

Tool Offset and Nose Radius Compensation

In turning operations, various types and different shapes of tools are used to finish one workpiece.

ID cutting tools, OD cutting tools, rough cut tools, finish cut tools, drills, etc. Accordingly, the tool

nose radius compensation function has to be activated simultaneously with the tool offset function.

LE33013R0300800020001

Tool Nose Radius Compensation at Discontinuous Point

LE33013R0300800020002

Point A in the figure above constitutes a discontinuous point and an angle less than 180

°

. By using

the tool nose radius compensation function, the tool path shown above can be generated by simply

entering the coordinates of points A and B.

Nose radius

compensation

Position

compensation

B'

A'

A

B