5238-E P-260

SECTION 11 PROGRAMMING FOR SIMULTANEOUS 4-AXIS CUTS (2S Model)

•

It is advisable to use two or three digits for P numbers, rather than just one, to make it easier to

correct programs.

3.

Precautions on Programming Simultaneous 4-axis Cuts

The key to efficient simultaneous 4-axis cuts on a 2S model is performing the intended cutting in a

well-balanced manner.

When programming simultaneous 4-axis cuts, observe the following points carefully:

Determine the extent of operations to be performed by turrets A and B.

The cutting times required for these two turrets should be well matched when determining the

sections to be cut by each.

Determine optimum cutting conditions.

•

Since a spindle change cannot be performed during a simultaneous 4-axis cut, the cutting

speed will vary according to the diameter being cut. Select the tip material carefully to suit the

workpiece material to be cut.

•

Select feedrate and depth of cut by taking the cutting at the two turrets into account:

Example:

LE33013R0301300060001

* If the P number in block N0002 is made, for example, P200, i.e., if the P number does not

match, the control first executes the commands in N0001 for turret A and those in N0101 for

turret B. After that, commands for turret B assigned a P number smaller than P200 are

executed, then the commands for turret A are executed from the block containing P200, i.e.,

N0001. Therefore, P numbers must be assigned sequentially (P10

→

P20

→

P30) in

accordance with the order of command execution.

Examples: P10 instead of P1

P20 instead of P2

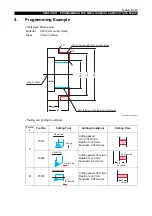

Depth of cut : 4 mm

Feedrate : 0.3 mm/rev

Turret A

Turret B

Depth of cut : 4 mm

Feedrate : 0.3 mm/rev

Cutting

time

Depth of cut : 4 mm

Feedrate : 0.35 mm/rev

Turret A

Turret B

Depth of cut : 3 mm

Feedrate : 0.35 mm/rev

Cutting

time

Reduction of cutting time