5238-E P-249

SECTION 9 CONTOUR GENERATION

•

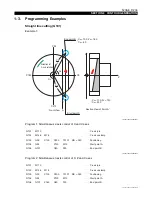

For circular interpolation between two points A and B on the side face, there are two possible

paths which have the same radius and a center angle of less than 180

°

since the C-axis is a

rotary axis and the coordinate values are continuous in 360 degree cycles.

LE33013R0301100070002

In such a case, an arc is generated according to M15/M16 (C-axis forward/reverse rotation

command) designated preceding the arc command.

Arc "a" is generated when M15 is designated.

Arc "b" is generated when M16 is designated.

The values in parentheses are for the inner plane (in both the figures and the text).

[Supplement]

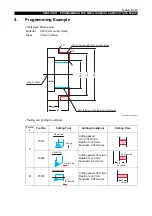

Side Contour Generation Programming Mode Function

•

Making the mode valid/invalid

The side contour generation programming mode function is valid when "1" is set at optional

parameter (bit) No. 56 bit 4.

When the C-axis is joined, machining is possible within a C-axis rotation range of 5965 turns (596

turns for the 0.1

µ

m specification) in one direction. If side contour generation machining that

exceeds this limit is carried out, the following alarm message is displayed.

Alarm B 2480 Profile generation calculation.

If this alarm message is displayed, use the side contour generation programming mode function.

The setting method is described below.

1:

Side contour generation programming mode function Valid

0:

Side contour generation programming mode function Invalid (initial setting)

(C359.999) C0

(C0) C359.999

(C0) C359.999

(C359.999) C0

Fig. 6

point A C80 (C280)

point B C260 (C100)

B

b

A

L

L

a

B