5238-E P-245

SECTION 9 CONTOUR GENERATION

(4) When the start and end points lie at the opposite sides of the C-axis center with the C-axis

commands at these points 180

°

apart:

LE33013R0301100040004

In this case, first only the X-axis moves until it reaches "0". Then, the C-axis moves by 180

degrees; after the completion of the 180-degree motion, the X-axis moves again.

In motions in (2), (3), and (4) above, C-axis motion is also controlled by the commanded

feedrate. It is possible to activate the C-axis feedrate override by the setting at C-axis center

override (%) of optional parameter (MULTIPLE MACHINING).

•

Special operation during G101 mode: Override value for C-axis feed is set.

Setting range: 1 - 1000 (Unit: %)

Initial value: 100 (%)

•

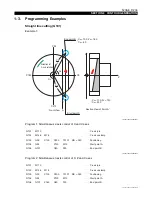

Automatic feedrate control function

If the commanded paths pass close the center of the X-C coordinate, the C-axis feedrate

calculated from the designated compound feedrate (compound feedrate of X and C axes) might

be excessively large.

LE33013R0301100040005

For the commanded feedrate F, the C-axis feedrates change in the sequence Ca, Cb, Cc and

Cf. In this case, the C-axis feedrate is the maximum at Cd.

An excessively large C-axis feedrate to provide the commanded feedrate will cause the CON

velocity alarm. The feedrate is limited automatically so that the C-axis feedrate will not exceed

the CON velocity limit.

In this case, however, the programmed feedrate changes during the execution of the

commands. Therefore, it is possible to ignore this automatic limitation by turning the automatic

control function OFF with the setting at Auto limit for C-axis feedrate of optional parameter

(MULTIPLE MACHINING).

C = 90

°

C = 0

°

End point

Start point

Ce

Cd

Cc

Cb

Ca

Cf

F

Programmed tool path