5238-E P-306

SECTION 12 USER TASK

3

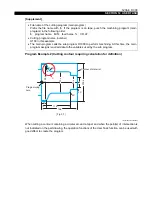

The elements (dimensions) used to define the contour, and the tool numbers and the cutting

speeds, are expressed using the local variables and the common variables, respectively.

LE33013R0301400490002

4

For cutting a workpiece, the LAP mode is used.

5

The steps described above are summarized in the table below.

•

Subprogram

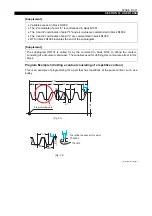

The subprogram defining the contour, prepared using local and common variables, can be

programmed as shown below on the basis of the table above.

LE33013R0301400490003

Roughing tool

Finishing tool

Cutting speed

in roughing

cycle

Cutting speed

in finishing

cycle

LZ1

LZ2

LZ3

DX1

DX2

DX3

WZ1

UX1

XS

ZS

V1

V2

V3

V4

LZ1

LZ2

LZ3

DX1

DX2

DX3

WLZ1

UDX1

XS

ZS

Workpiece A

Shaft-A

0101

0202

100

120

200

150

80

30

50

80

0.1

0.2

100

210

Workpiece B

Shaft-B

0303

0404

110

130

250

170

100

40

70

120

0.15

0.25

140

260

Workpiece C

Shaft-C

0505

0606

90

150

300

200

120

50

90

150

0.2

0.3

170

300

V1 = Roughing tool

V2 = Finishing tool

V3 = Cutting speed in roughing cycle

V4 = Cutting speed in finishing cycle

LZ1 = Longitudinal dimension LZ1

LZ2 = Longitudinal dimension LZ2

LZ3 = Longitudinal dimension LZ3

DX1 = Diameter DX1

DX2 = Diameter DX2

DX3 = Diameter DX3

WLZ1 = Finish allowance in longitudinal direction (WZ1)

UDX1 = Finish allowance on diameter (UX1)

XS = X coordinate of LAP starting point

ZS = Z coordinate of LAP starting point

O1000

NLAP1

N1001

N1002

N1003

N1004

N1005

N1006

N1007

N1010

N1011

N1012

N1020

N1021

N1022

F0.35 U=UDX1 W=WLZ1

Z=LZ1+2

F0.2

Z=LZ3

Z=0

Z=400

S=V3 T=V1 M03 M08

D4

Z=400

X=DX1

Z=LZ2

X=DX2

X=DX3

X=800

X=XS

NLAP1

X=800

NLAP1

G81

G00

G01

G80

G00

G96

G85

G00

G87

$ SHAFT-ABC.SUB %