5238-E P-203

SECTION 8 LATHE AUTO-PROGRAMMING FUNCTION (LAP)

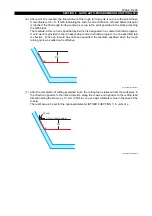

(7) Calls for finish turning cycle

Finish turning cycle is carried out by designating G87 and calling for the finish contour definition

blocks starting with G81 or G82.

[Supplement]

10-4-3. Outline of High-speed Bar Turning Cycle

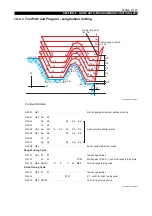

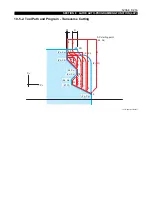

Rough turning cycle in the longitudinal direction (example A)

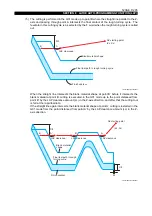

(1) The commands in block N0161 position the axes at the tool change point.

(2) With the commands in block N0162, S, T and M commands for the rough turning cycle are

selected, then the axes are positioned at the LAP starting point.

When no S, T, or M command is designated in this block, those selected in the preceding

block(s) are effective.

(3) The NAT60 command in block N0163 causes the control to search for the program assigned

the program name NAT60. The rough turning cycle in the bar turning mode is performed with

this program.

When NAT60 is designated in the block starting with G83, a high-speed bar turning cycle

(LAP4) is carried out.

The cutting conditions for the rough turning cycle are also specified in this block.

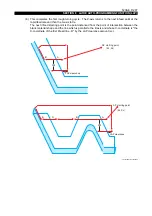

1) The blank material shape definition must always come before the blocks defining the finish

contour.

2) The blank material shape must be defined in the same direction as the finish contour is defined.

3) The start point of the blank material shape is identical to the start point of the machining shape.

4) The end point of the blank material shape is identical to the end point of the machining shape.

D

: Depth of cut

F

: Feedrate

U

: X component of stock removal in finish turning cycle

W : Z component of stock removal in finish turning cycle

End point Extension of

end point End point Blank material shape

Cutting area

Start point

Extension of

start point

Start point

Finish contour